Big Bag Unloading Station

It is mainly used for unpacking and unloading the material packed in a big bag. The big bag is lifted to the rack with an electric hoist, and the discharge port under the big bag is manually opened. Material falls by gravity into the silo. Different models are available according to working conditions, plant layout, process and material properties on site.

Jet Mill

LQM series jet mill is a professional crushing equipment developed by ONGOAL for the characteristics of battery materials, with high crushing efficiency, low energy consumption, concentrated particle size distribution and no pollution, which is perfectly suited for the production of battery materials.

Low Speed Kettle Dryer

The dryer uses traditional hot oil heating to dry material while stirring it. Fast drying and higher efficiency are achieved since the water boiling point is lower and evaporation is more rapid in a high vacuum environment. It adopts the low-speed stirring process to avoid damage to the coating layer and the increase of powder crushing rate caused by the extrusion and collision between material particles. It is mainly used for the production of battery materials.

Paddle Mixer

It is mainly used for mixing powder or powder adding a small amount of liquid. It solves the problems of low uniformity and dead angle caused by different specific gravity of materials. When the equipment is running, the paddle moves the material to the entire vessel space, so that the material is in an instant weightless state, widely interlaced with convection and diffusion,so as to achieve a uniform mixing effect. It’s also called a gravity-free mixer

Semi-auto Iron Remover

The semiautomatic iron remover is mainly used to eliminate magnetic impurities from slurries. It is connected in line with the slurry pipeline, and when in use, the slurry flows through the interior of the iron remover. Using a high-intensity 12,000 Gauss magnetic rod effectively removes magnetic impurities from the slurry.

High Gravity Material Dispense Mixer

The high gravity material dispense mixer is mainly used for fast, uniform and sedimentation free mixing of liquid-solid materials. It can disperse high-density solid granule such as ceramic materials, ferrite magnetic materials, powder metallurgy materials, chemical catalyst materials, etc. The equipment combines anchor paddle and square paddle, and adopts the operation mode of "high-speed dispersion and low-speed discharge". During operation, the materials can be three-dimensional tumbled, and the mixing effect is better.

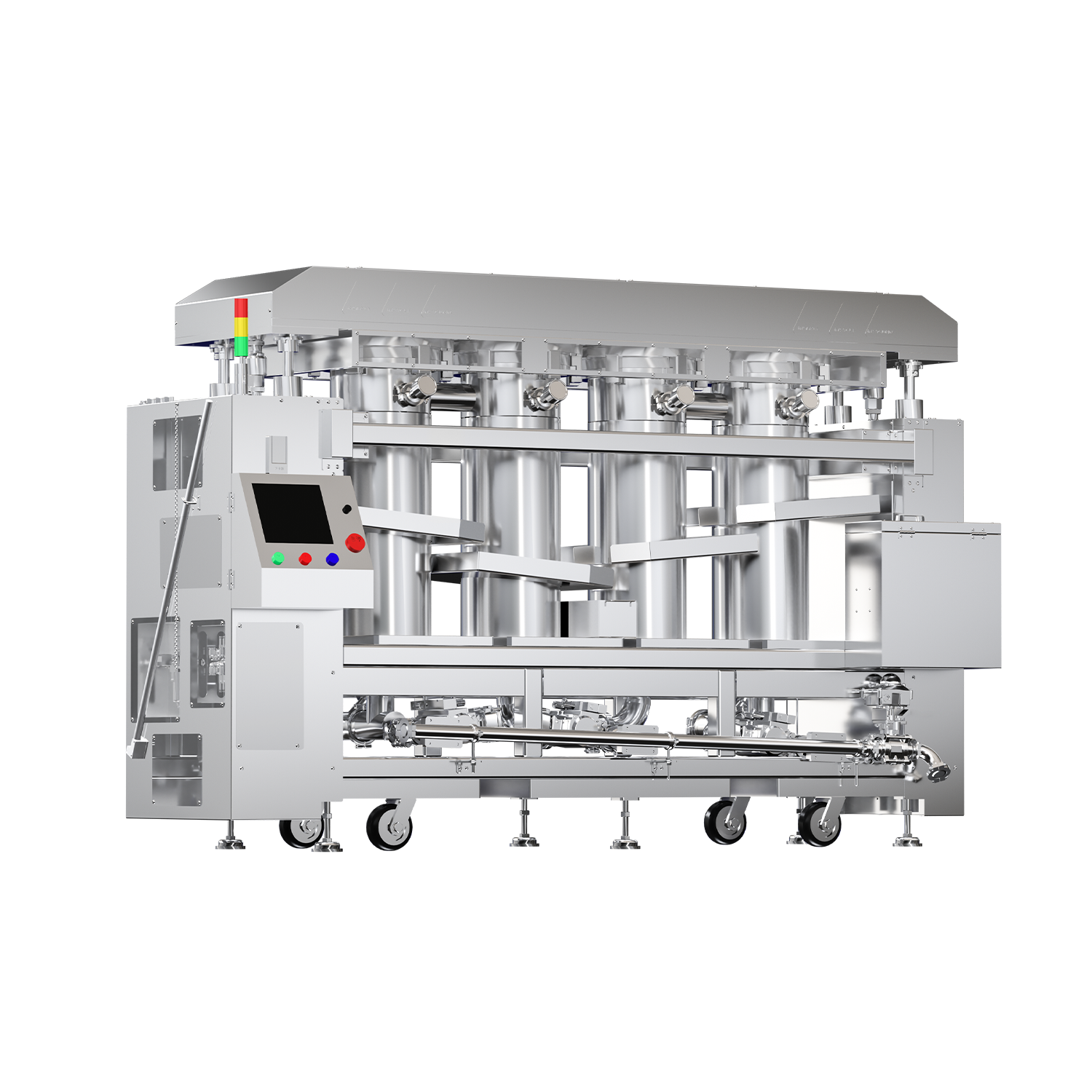

Multi-components Suction and Weighing Scale

As an ONGOAL proprietary patent product, the Multi-components Suction and Weighing Scale integrates suction, dosing, weighing and conveying for powder and granule. The system adopts automatic cycle control and uses negative pressure to suction feed material to storage bin while weighing. It can dose up to 24 different kinds of material simultaneously

IBC Rotary Mixer

lBC Rotary Mixer is designed to meet the production requirements of multiple formulationsmultiple batches, and a wide range of product types, it uses the bin as a batch for productionand offers strong flexibility, high efficiency, and easy cleaning as its main features.