Product Features

Product Video

Video Introduction

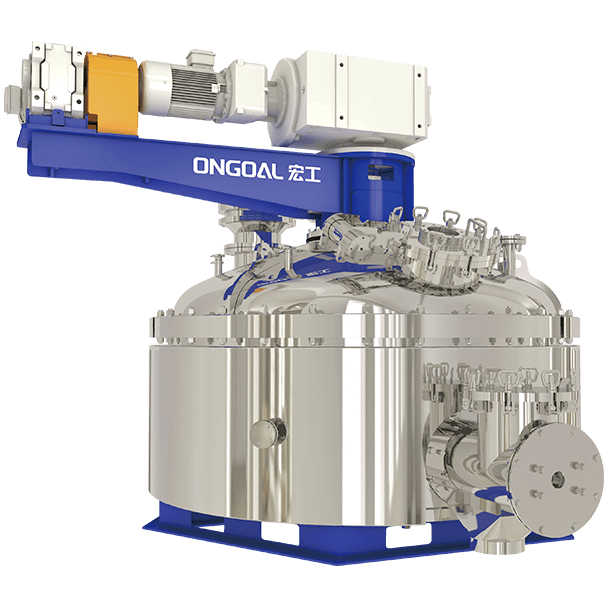

Product Introduction

Optimized by simulation, the stirring paddle moves central material downward and material at the bottom and near the vessel wall upward to ensure uniform heating and better stirring effect.

01

The 3-leaf paddle is densely distributed with pressure vent hole to prevent material covering the paddle and increase motor loading. Depressurization process will not affect the stirring. Self-adjusting scrapping device and evolvent scrapper collaborate to ensure complete material discharge.

02

The kettle and hot oil channel lining are made of high heat conductive ceramic according to pressure vessel standard to ensure both high heat exchage and risk-proof of metal pollution. The bee hive structure of the hot oil channel ensures enough strength.

03

Outlet with proprietary design brings better sealing. A blowing nozzle ensures the plane of the sealing is clean after material discharged.

04

The hot oil deflector at the bottom and along the side wall adopts optimized channel to ensure high flow velocity and turbulance and higher heat exchange rate. An oil inflation and circulation pressure detector are used to avoid damage to equipment in any accident.

05

Product Specifications

Low Speed Kettle Dryer

Note: The contents in this document are for information purposes only, and the actual product parameters depend on the specific design scheme

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply