Twin-Screw Slurry Mixing System

The equipment adopts modular twin-screw structure, integrating conveying, mixing, dispersing and exhausting in one, which can realize continuous material processing and discharging and free collocation to meet the demand of different working conditions and lower cost and energy loss caused by single function.

Solution Features

Solution Introduction

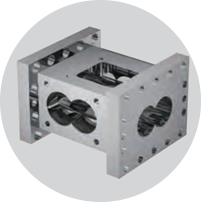

The vessels adopts nested modular structure. Among them, the outer vessel is set up

with multi-channel cooling for precise temperature control and the inner vessel

is made of high wear-resistant and corrosion-resistant material, which can

reduce magnetic contamination and lower the cost of manufacture and

maintenance, making it easy to install and replace.

01

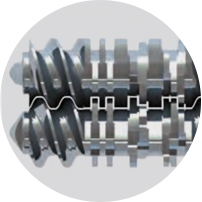

The screw adopts modular structure. Screw and the threaded block are linked

by involute splines for precise positioning, stable structure and reliable transmission.

02

Using a variety of sizes of threaded blocks to bring fast kneading and dispersing. It

realizes conveying, mixing and dispersing battery slurry on a set of twin screws to

achieve optimal materials processing.

03

By adopting the same direction kneading twin screw, the material is subjected to roller pressure and gradient reverse speed, which forms a

8-channel conveying. Screw floats up, avoiding the friction between the screw and the vessel wall so that the material is evenly mixed

and dispersed; conjugate screws offer good self-cleaning function.

04

Customer Stories