Product Features

Product Introduction

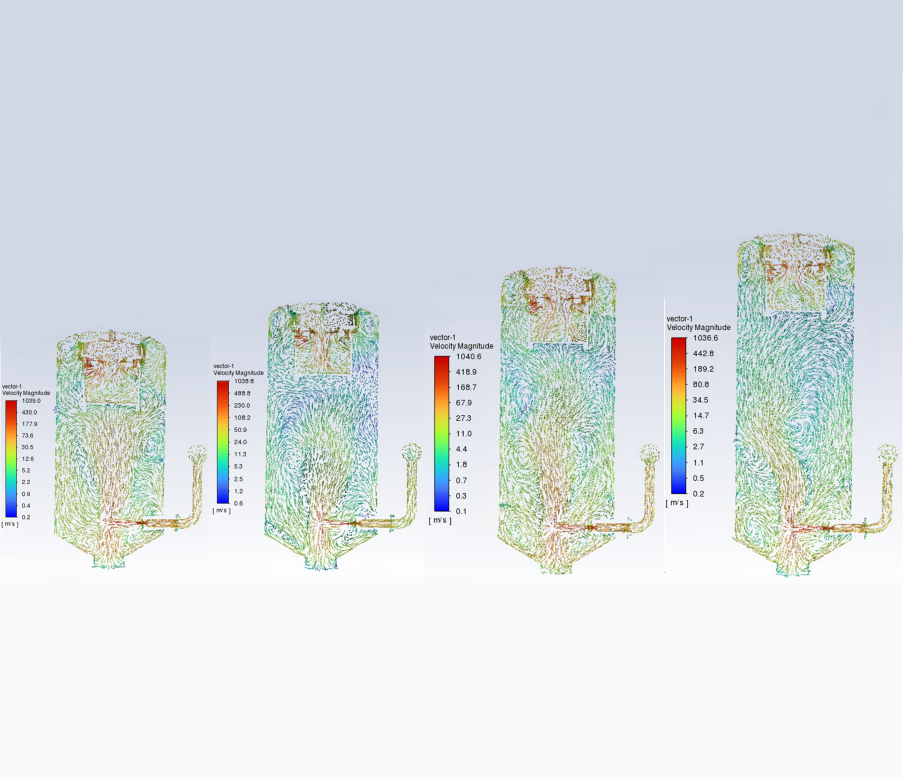

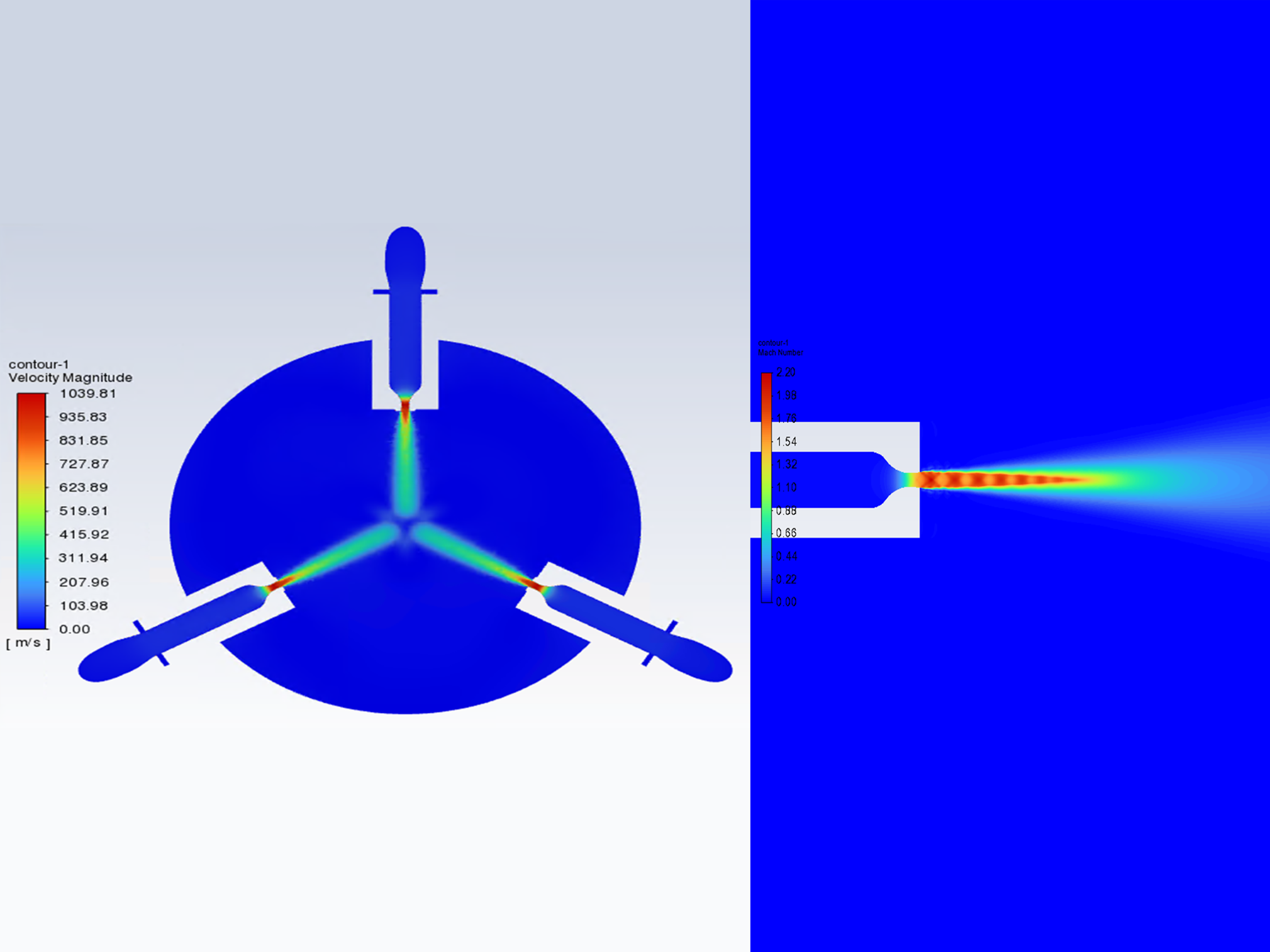

By conducting numerous simulation experiments, the optimal selection of nozzles, grading wheels, chamber structures, and matching sizes and parameters has been achieved. This has effectively reduced energy consumption and crushing rate.

01

The grading wheel and nozzle adopt full ceramic structure, which effectively reduces the metal foreign matter in the material.

02

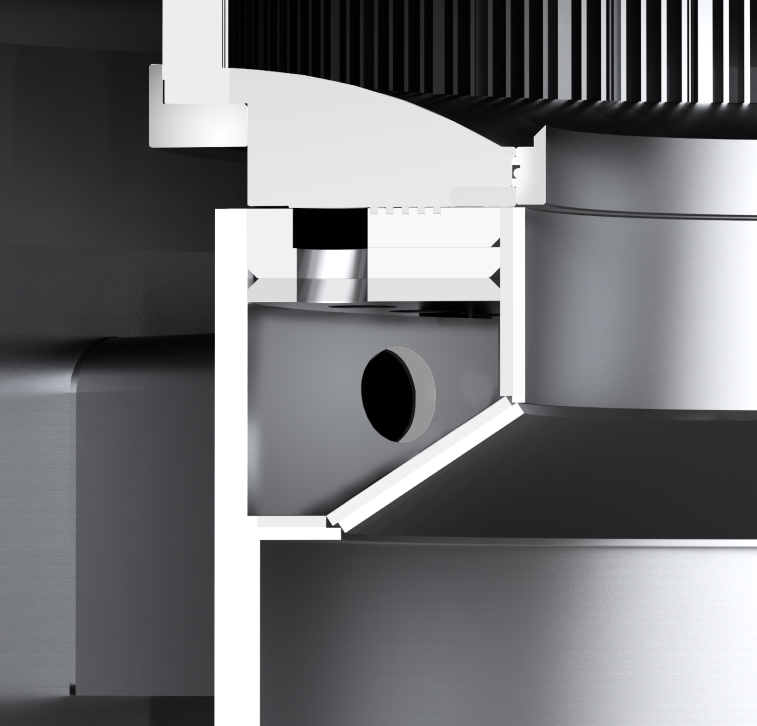

Adopting labyrinth sealing + gas sealing, effectively controlling the escape of large particles, high qualified rate of finished products.

03

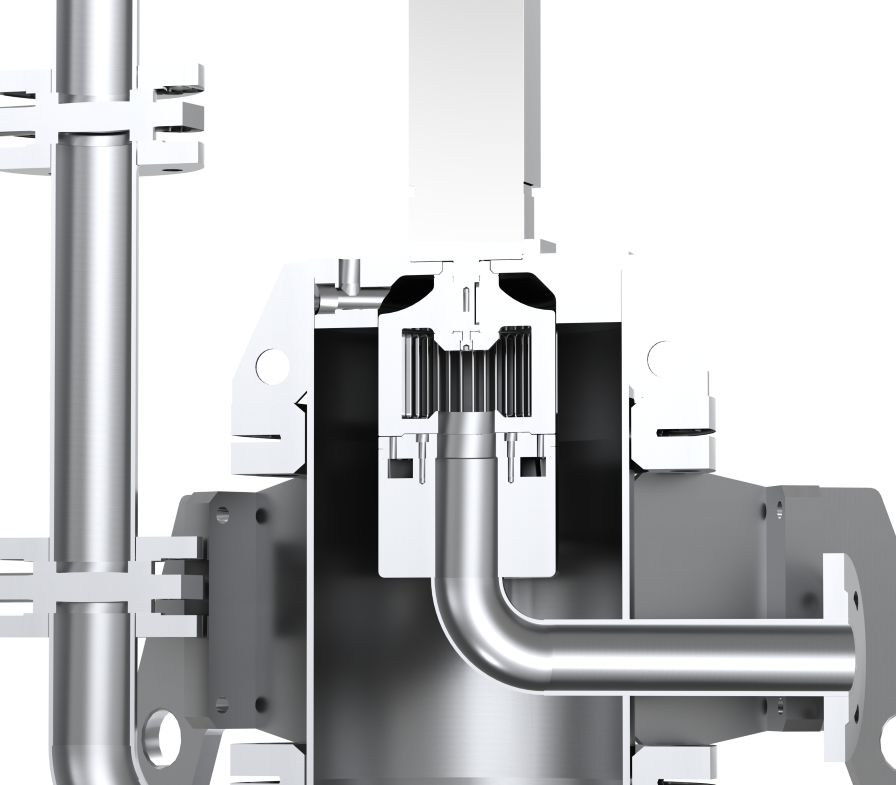

The grading wheel adopts vertical arrangement, with high grading efficiency, centralized particle size distribution and more precise regulation.

04

Using a three-nozzle structural arrangement, the air consumption per unit is 60-70m³/min, reducing energy loss due to air flow collision. Compared to similar products, the air consumption per unit can be reduced by around 50%, thus significantly lowering energy consumption.

05

Product Specifications

Jet Mill

| Item |

LQM800

|

LQM1200

|

LQM1500

|

LQM1800

|

|

Capacity

|

1000

|

1800

|

2600

|

3600

|

|

Gas consumption

|

1920

|

3860

|

5770

|

8930

|

|

Grinding particle size

|

0.3~90

|

0.3~90

|

0.3~90

|

0.3~90

|

|

Grading wheel power

|

15 | 30 | 45 | 75 |

|

Maximum speed of grading wheel

|

3600

|

2300

|

2200

|

1700

|

|

Nozzle number

|

3 | 3 | 4 | 4 |

|

Grinding chamber diameter

|

800

|

1200

|

1500 | 1800 |

|

Total weight

|

5000

|

7500

|

15000

|

26500

|

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply