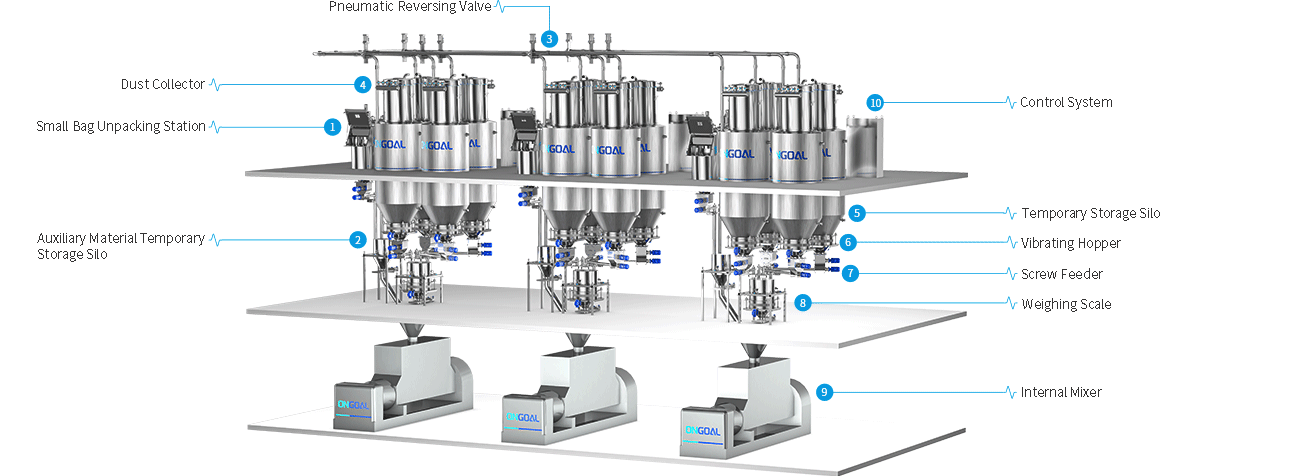

One-Stop Solution For Internal Mixer Batching System

Commonly used in rubber moulding and compounding for the automatic dosing of powders and granules. The system consists of unpacking system, storage system, conveying system, metering system and control system.

Solution Features

Application industry

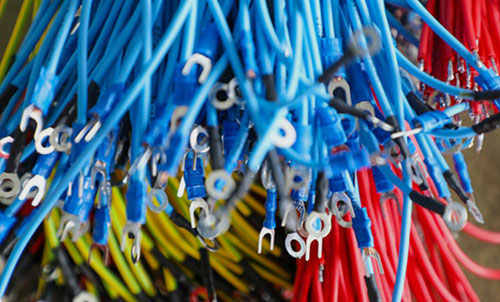

Wire & Cable

Engineering Plastics

Modified Plastics

Degradable Plastics

Polymer Materials

PVC flooring

Customer Stories