Product Features

Product Video

Video Introduction

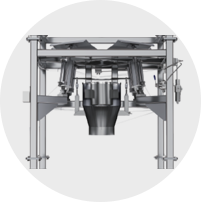

Product Introduction

Scan gun and touch panel to avoid feeding error

01

Airbag clamp sealing with closed discharge to prevent powder leakage

02

Pneumatic plate kneads the ton bag to allow material to discharge, increasing efficiency

03

Clean girder crane and electric hoist fix the ton bag and pull it straight to assist discharge

04

Product Specifications

Big Bag Unloading Station

Note: The contents in this document are for information purposes only, and the actual product parameters depend on the specific design scheme

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply