Product Features

Product Video

Video Introduction

Product Introduction

Colters are 90° & circumferential designed, gap between colter and wall is 4-7mm, which greatly improves the mixing uniformity.

01

Interlocking ceramic sheet + high-strength adhesive bond to achieve longer service life.

02

Improve sealing structure of shaft seal, discharge plate and colter parts to eliminate leaking risk of dust during operation.

03

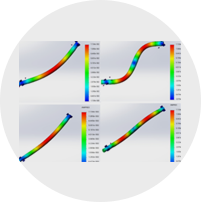

During operation, Max. vibration value 2.5mm/s is far lower than the required value (11.2mm / s) and Max. noise value 83db is lower than the required value of 85dB.

04

Improve sealing structure of shaft seal and colter parts for convenient maintenance by pulling out parts at one time.

05

Product Specifications

Ploughshare Mixer

Note: The motor power needs to be adjusted according to the characteristics of the material

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply