Product Features

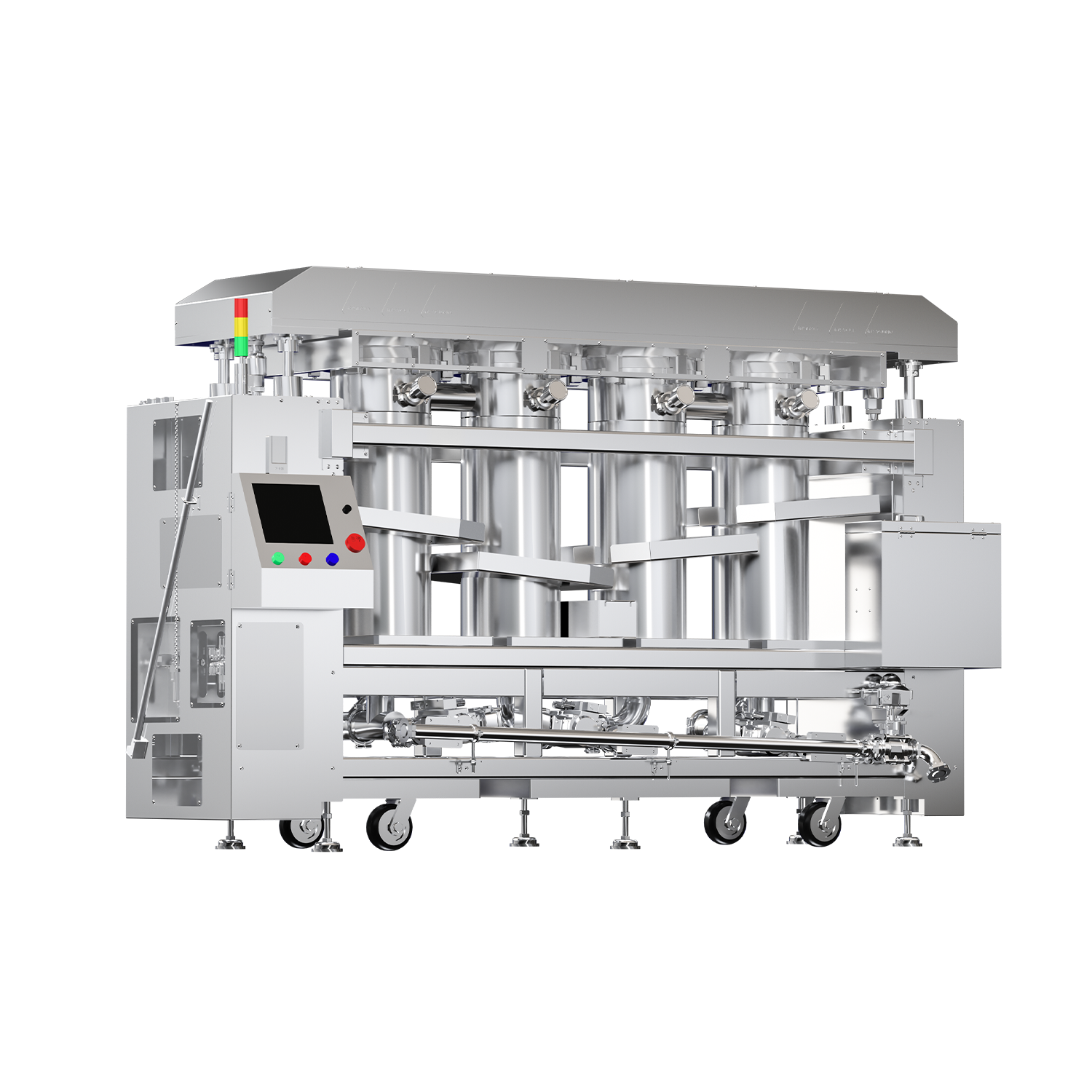

Product Introduction

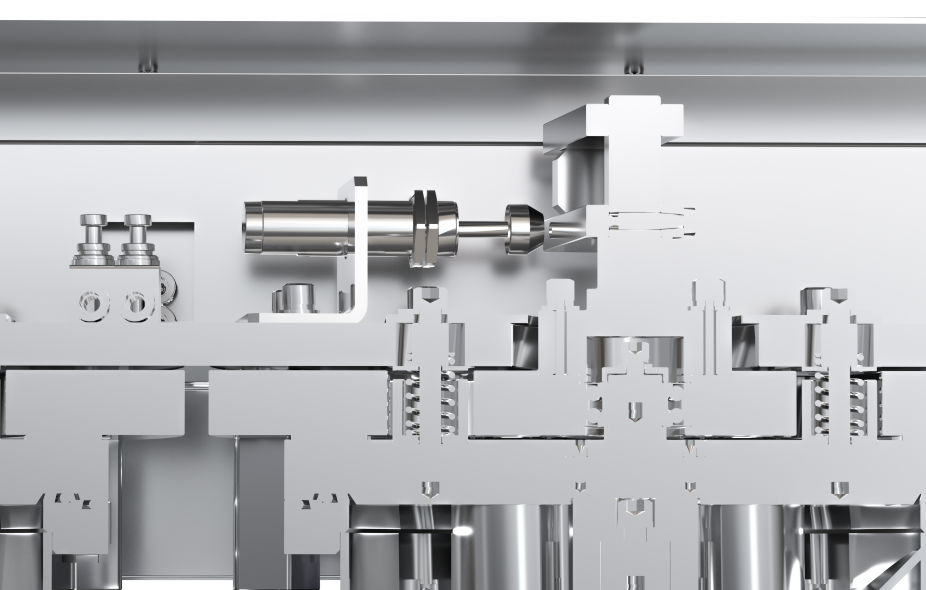

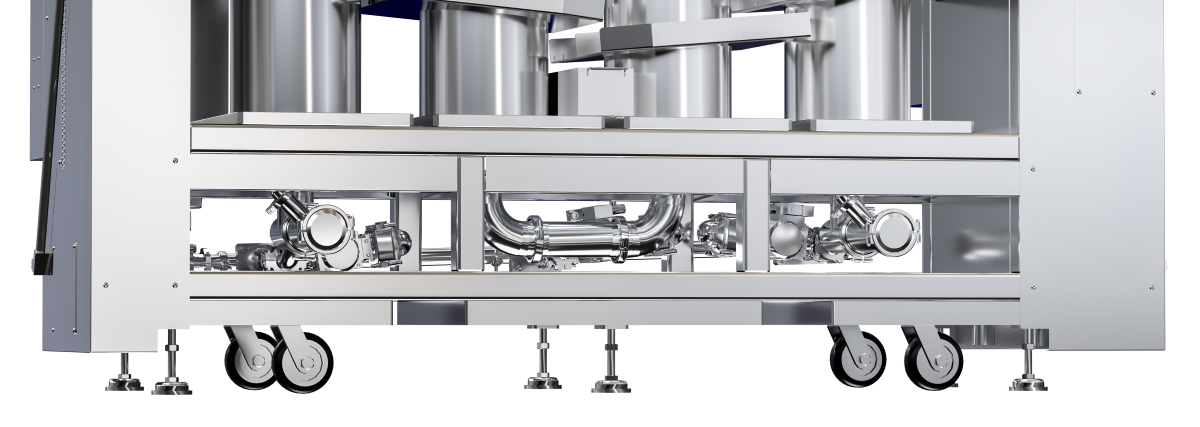

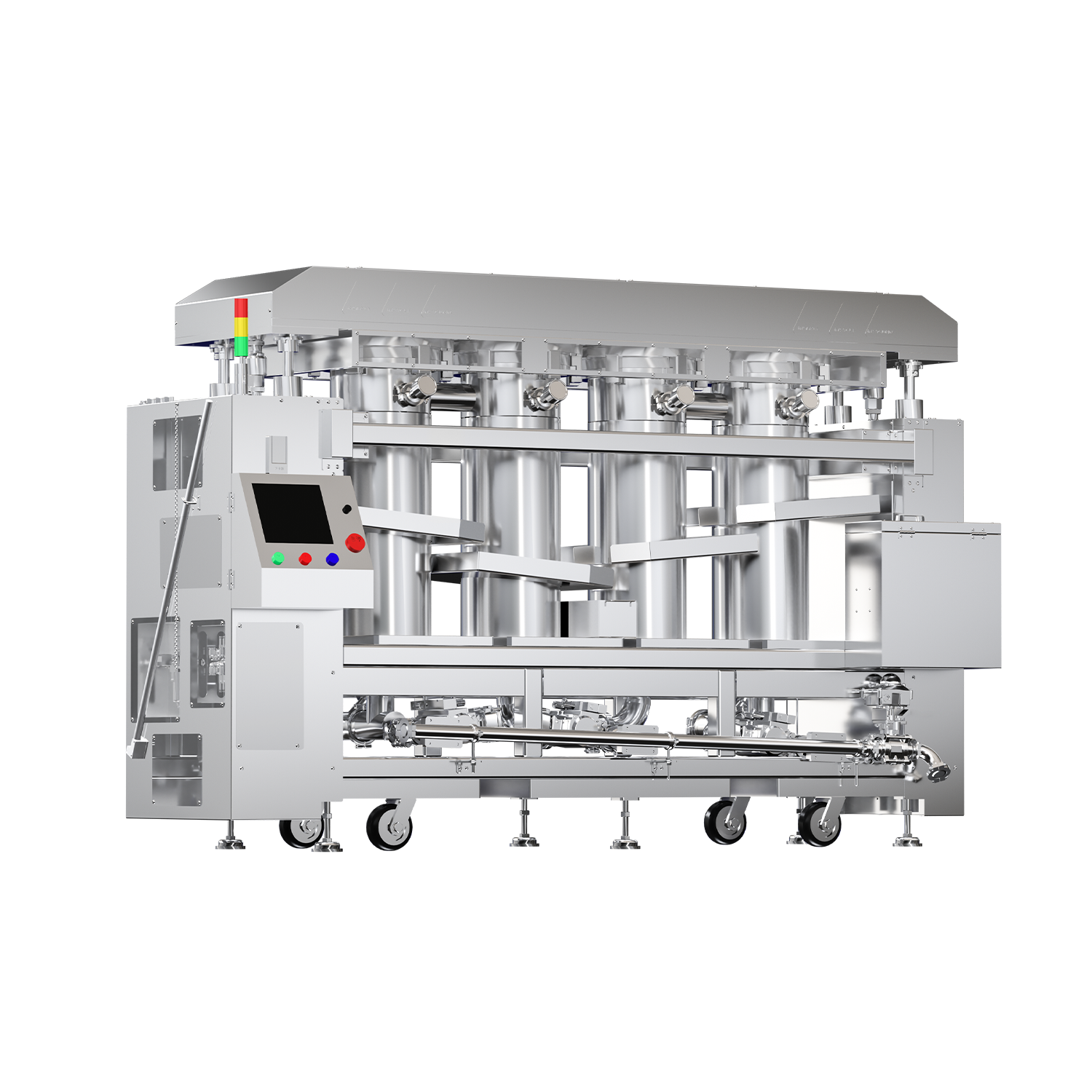

Maintenance is straightforward, and the equipment can be used immediately after replacing vulnerable components without the need for reconfiguration.

01

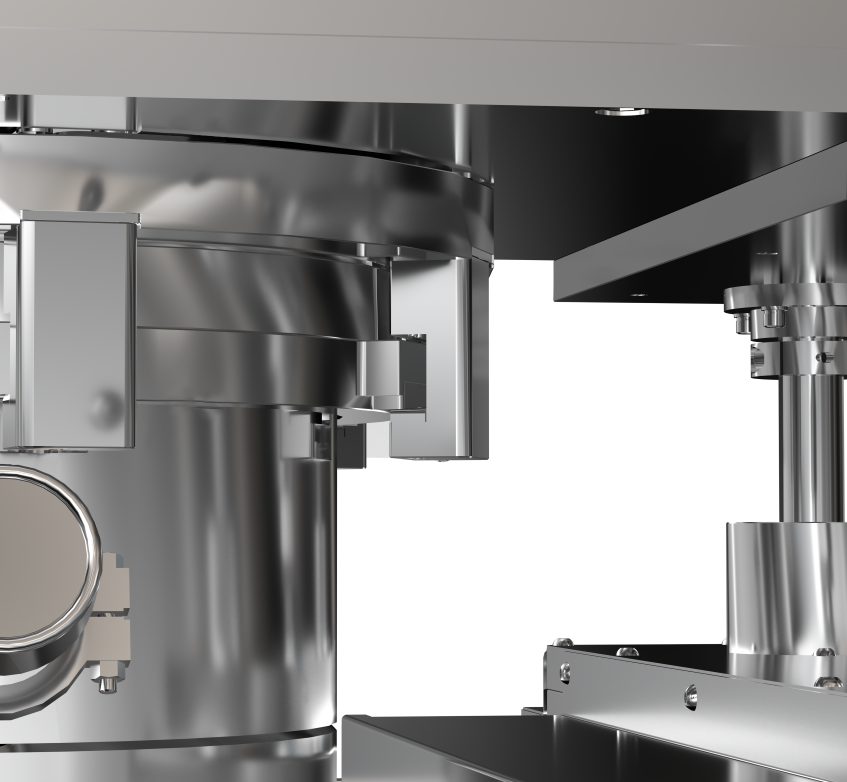

When cleaning the magnetic rod, a customized one-touch automatic pressure relief solution can be implemented to prevent slurry wastage and mitigate the risk of manual pressure relief.

02

Flexible locking connections ensure a tight fit after each locking, preventing material leakage.

03

The equipment is equipped with multiple safety measures, including automatic and manual safeguards, and program interlocking, ensuring safer operation.

04

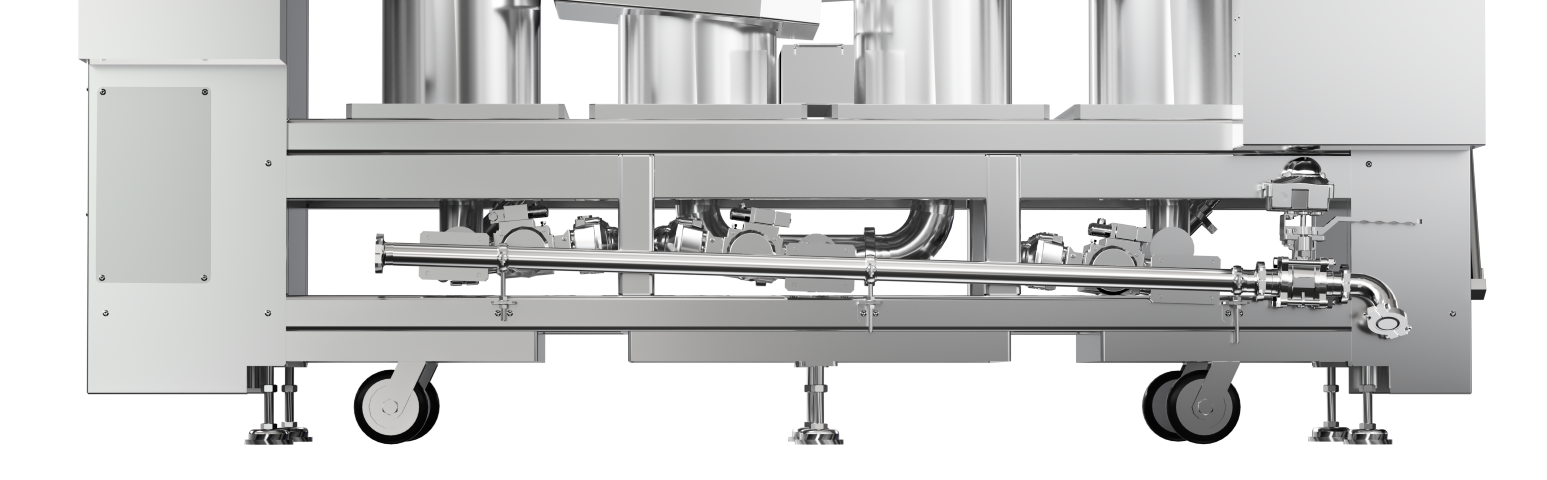

Equipment's inlet and outlet are at the same height and diameter, interchangeable, providing flexibility in equipment placement and adjustment.

05

Product Specifications

Semi-auto Iron Remover

| Model |

Design Flow

|

Magnetic Bar Diameter

|

Magnetic Strength

|

Pipe Diameter

|

|

HG-YCC-30

|

0-60

|

32

|

12000

|

76

|

|

HG-YCC-69

|

60-100

|

50

|

12000-15000

|

85

|

|

HG-YCC-100

|

100-120

|

50

|

12000-15000

|

102

|

Note: PLC control system can prestore various process data, record process data and provide Ethernet interface. The contents in this document are for information purposes only, and the actual product parameters depend on the specific design scheme

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply