Product Features

Product Video

Video Introduction

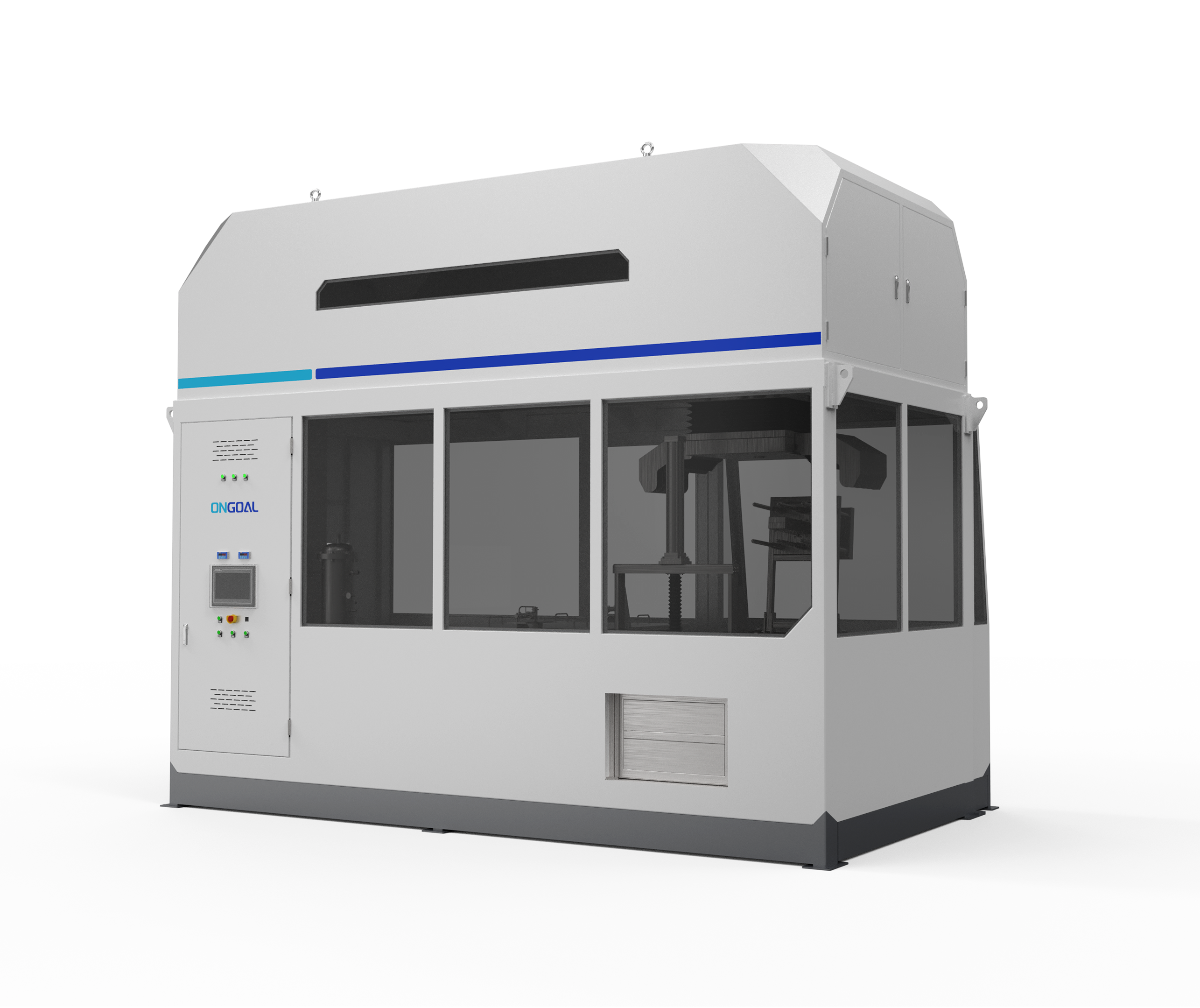

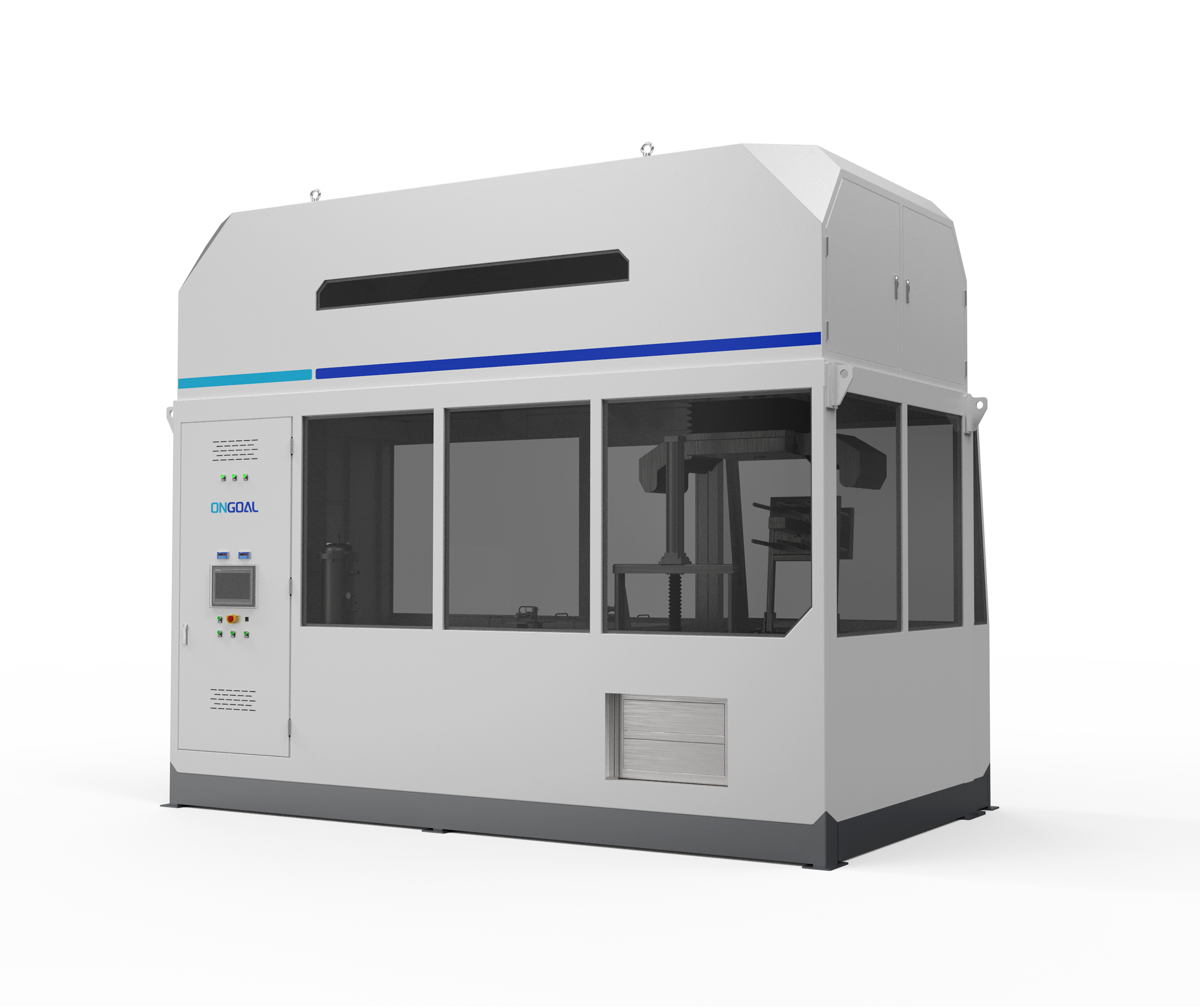

Product Introduction

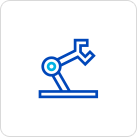

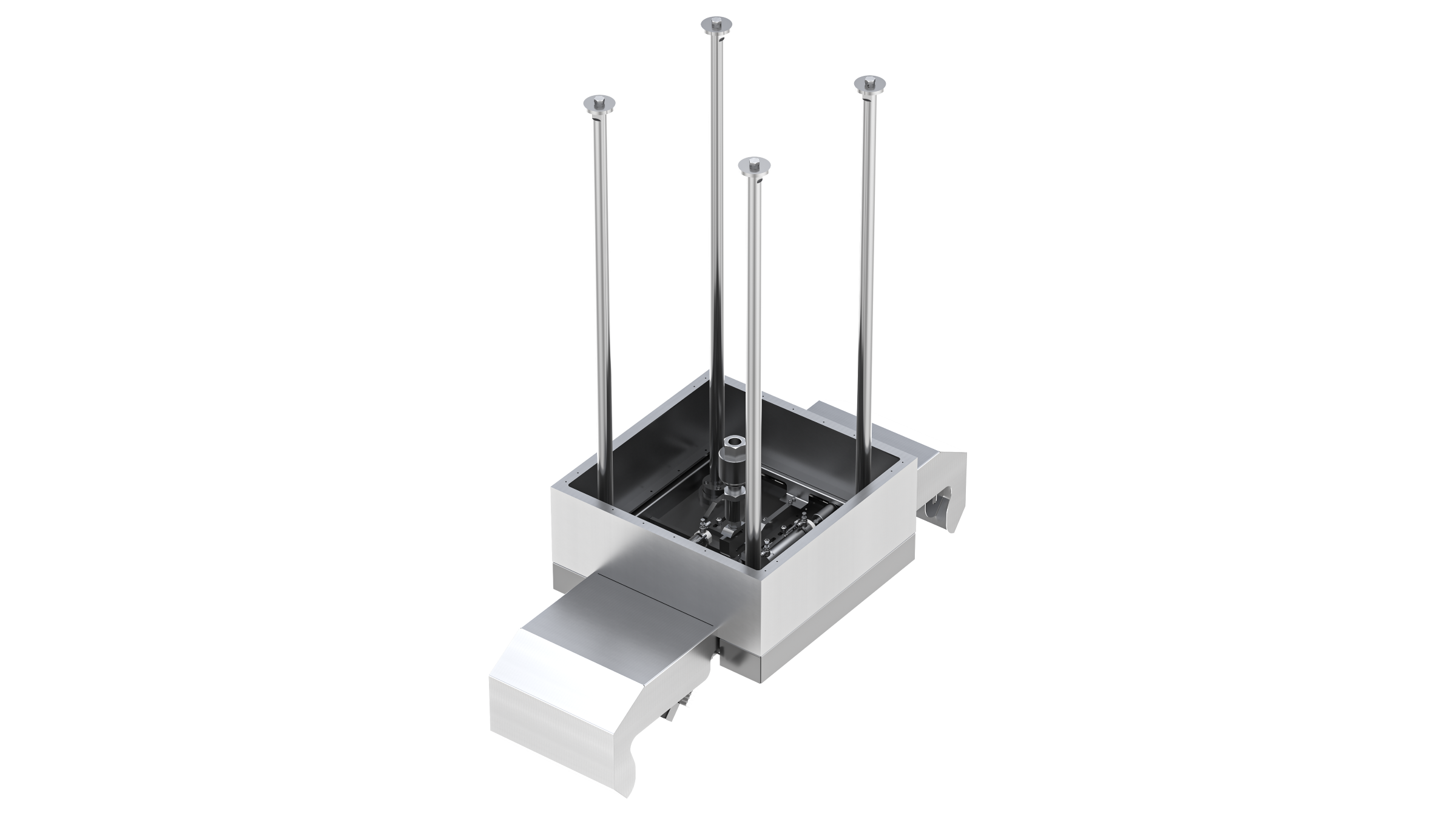

To achieve rapid bag breaking and forced discharging, a powerful kneading device is used to forcefully discharge the material from the big bag, followed by the combined action of strong lifting and bag shaking to ensure stable and rapid discharging of the material.

01

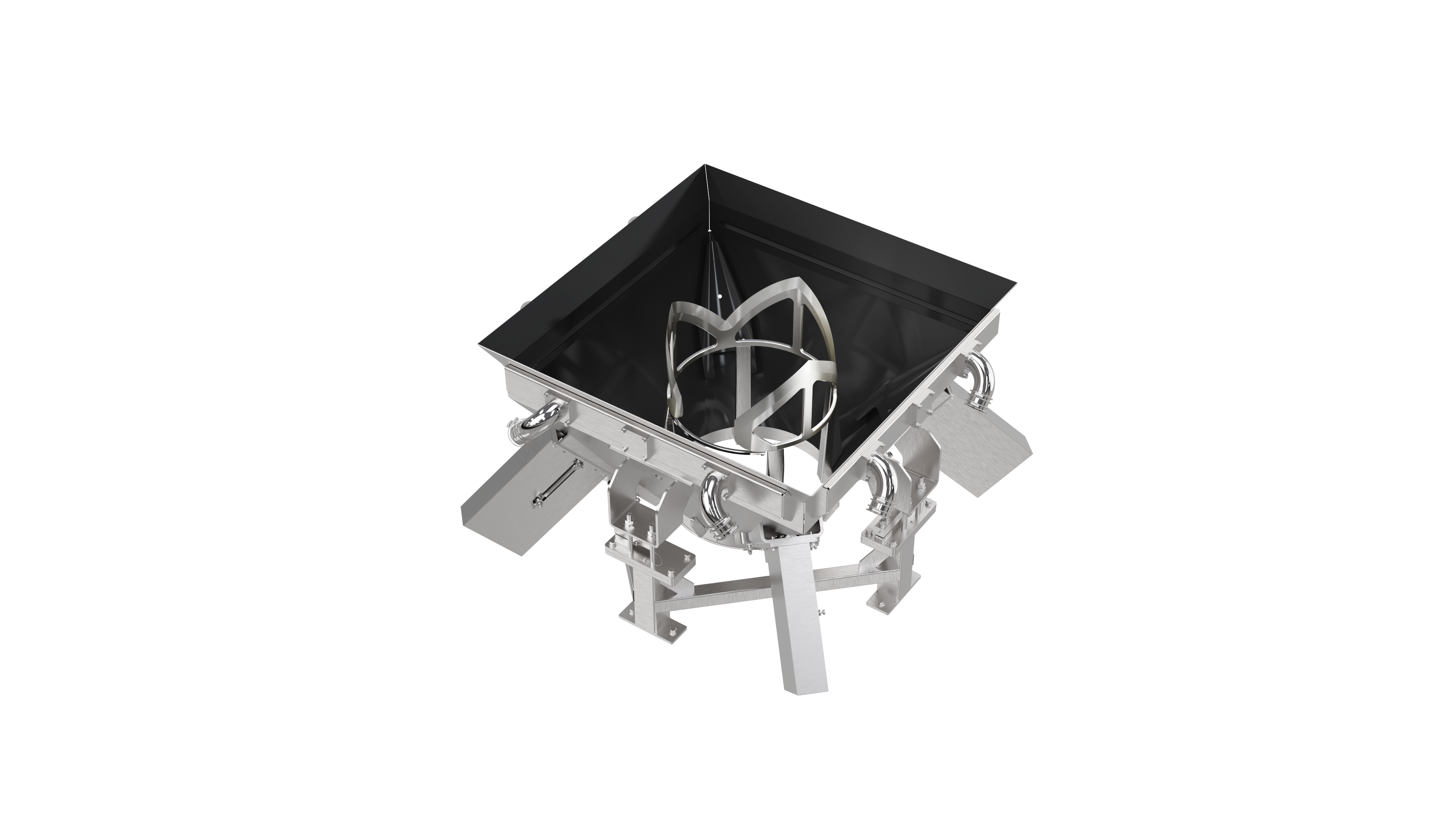

The system features separate functions for dust removal, dust collection, and waste bag recycle. Waste bags are processed through a multi-stage bag squeezing mechanism to ensure effective squeezing to address waste bag recycle and dust flowing issues.

02

Bag recycle mechanism utilizes a rod-type structure to push and align the bags, preventing bag detachment and achieving automatic recycle of waste bags

03

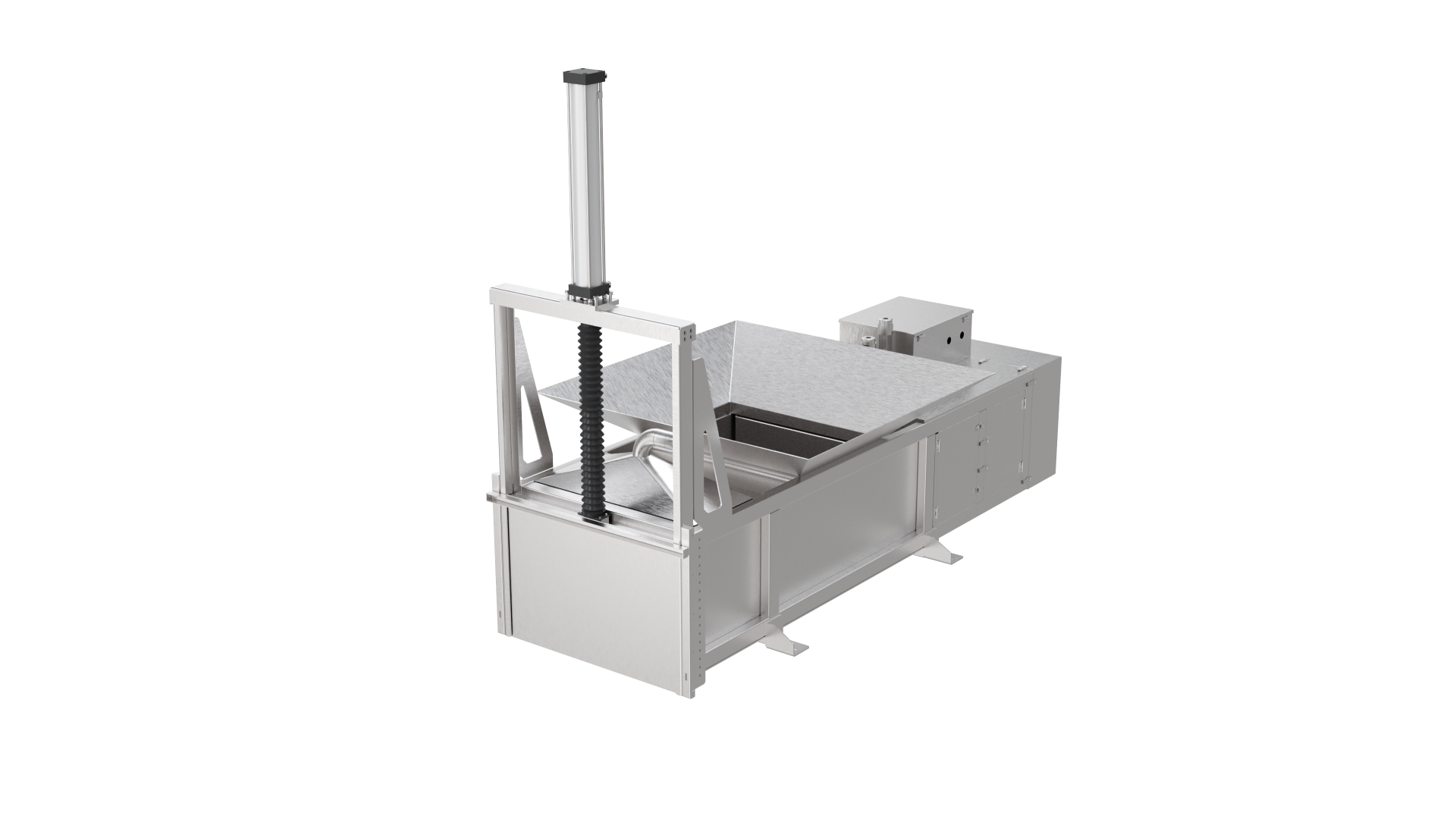

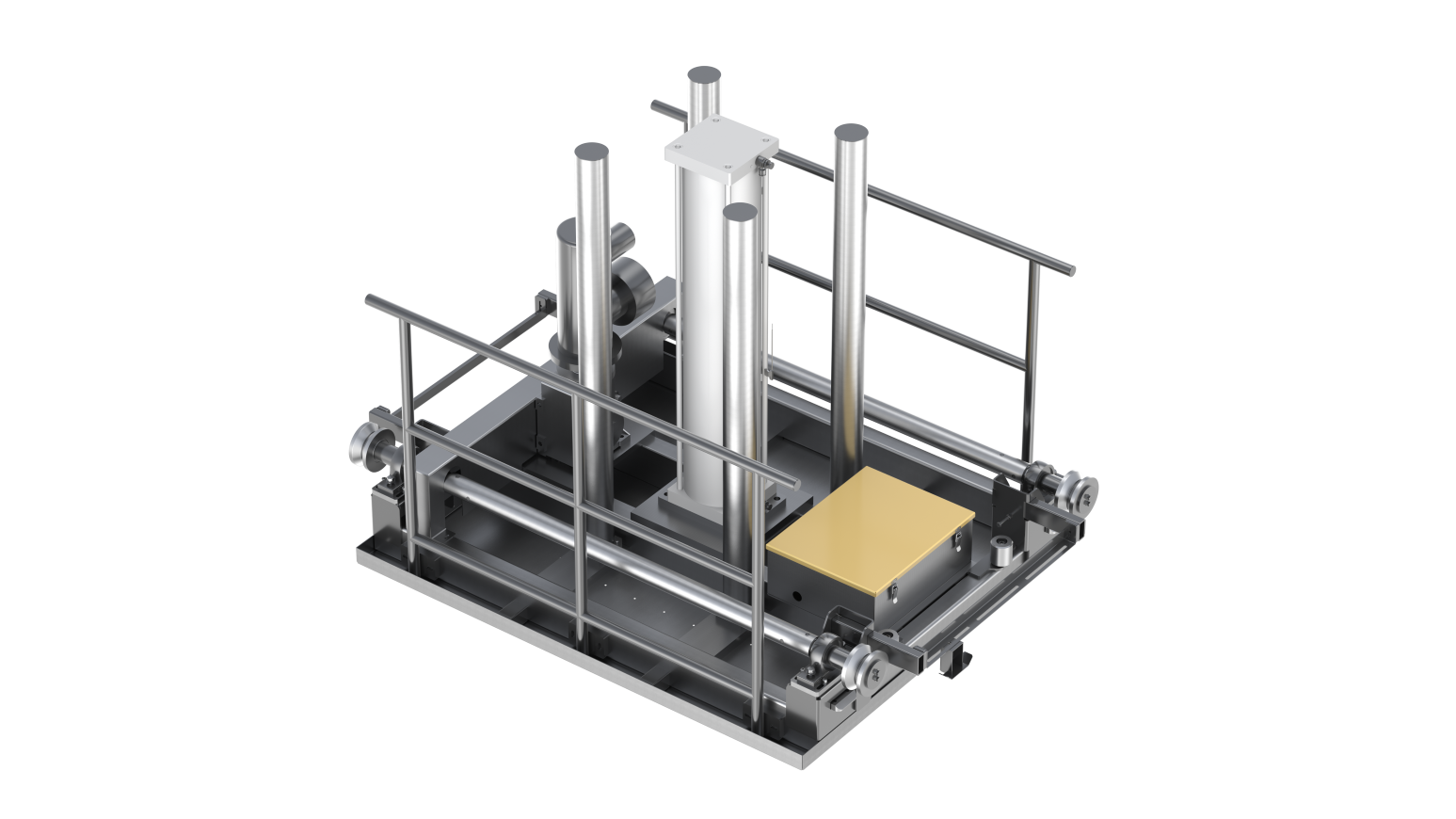

The mobile mechanism adopts synchronous wheel synchronous belt transmission and is designed with transmission protective covers and an integrated bottom material receiving tray structure to prevent fasteners from falling and reduce the generation of magnetic foreign objects.

04

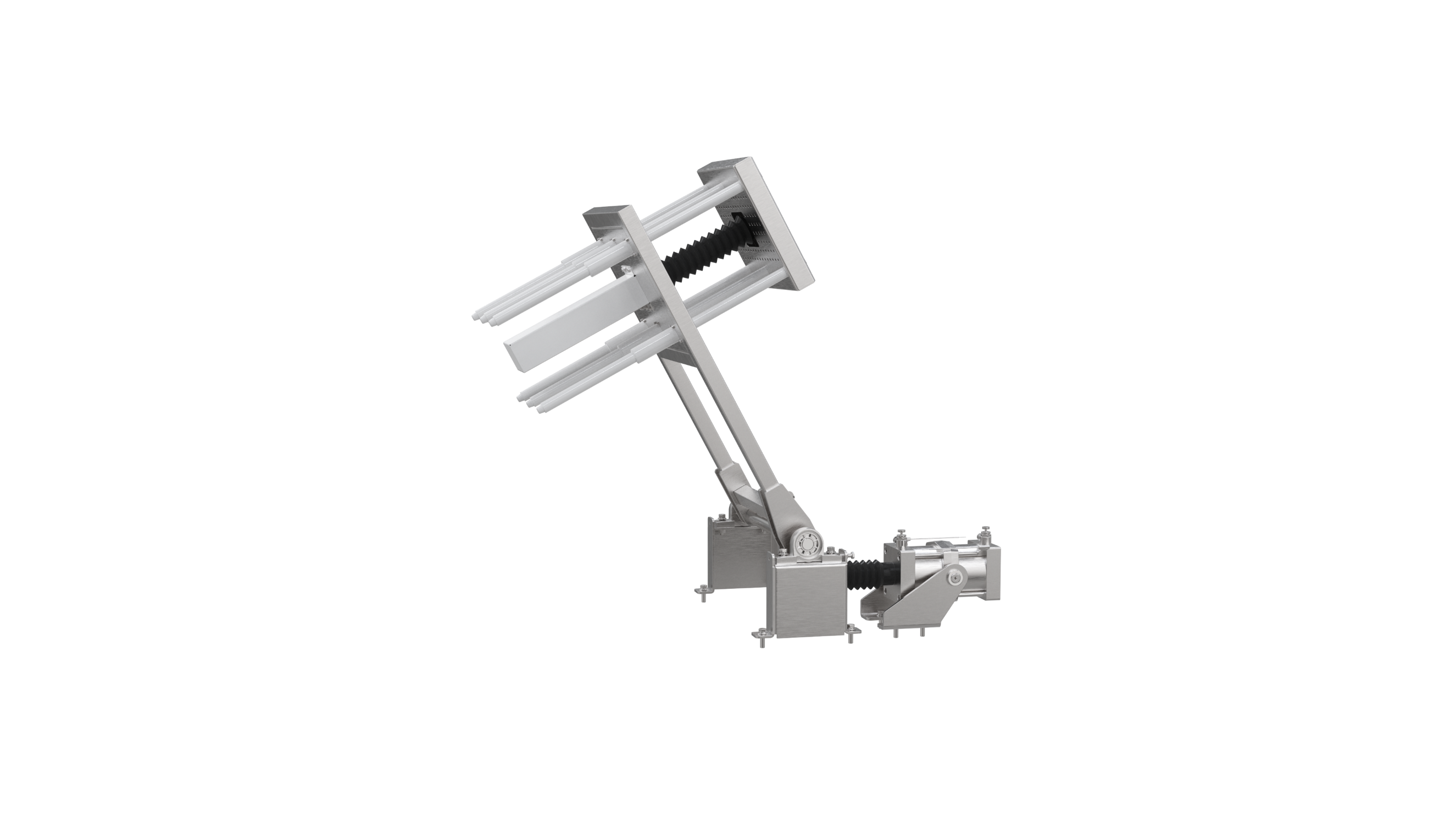

The fully automatic big bag grabbing mechanism adopts a double floating hook design, which grips the lateral encircling strap of the big bag. It adapts to the variations in the big bag's side using the floating hooks and features self-detection and self-alignment functions, ensuring stable gripping of the big bag.

05

Product Specifications

Fully Automatic Big Bag Unpacking Machine

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply