Product Features

Product Video

Video Introduction

Product Introduction

Adopt high precision gears with more accurate moving track to realize higher homogenization uniformity and production efficiency

01

The dispersing disc and stirring paddle realize revolution and rotation simultaneosly.

02

The planetary shaft adopts supporting beam structure with high support strength and higher critical speed. The equipment does not resonate under high speed conditions.

03

The planetary box adopts silicone elastic sealing plate with reliable sealing and no dust accumulation area. Can be filled with Nitrogen to form positive pressure zone to prevent dust from rising and prevent dry powder from falling when discharging

04

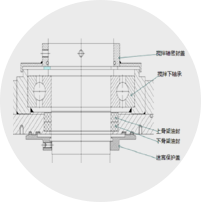

Adopts multiple combined seals to improve service life of dispersing bearings and to ensure the safety of materials. Equipped with oil storage chamber, when the dispersing bearings are damaged, the lubricant leaking from the bearings will directly flow into the chamber without pollution on the material.

05

Product Specifications

Dual Planetary Mixer

|

Models

|

Design Capacity

(L/h)

|

Internal Diameter

(mm)

|

MixingPower

(kW)

|

Revolution Speed

(r/min)

|

Mixing Speed

(r/min)

|

Dispersion Power

(kW)

|

Dispersion Speed

(r/min)

|

Linear Velocity

(r/min)

|

| JBZ5 |

7.4/5

|

Φ250*150

|

1.5

|

28±1

|

48±2

|

2.2

|

6500

|

18.7

|

| JBZ10 |

14/10

|

Φ300*200

|

2.2

|

28±1

|

48±2

|

3

|

5200

|

18.7

|

| JBZ30 |

44/30

|

Φ400*350

|

4

|

28±1

|

48±2

|

5.5

|

4200

|

18.8

|

| JBZ60 |

88/60

|

Φ500*450

|

7.5

|

28±1

|

46±2

|

11

|

3200

|

20.1

|

| JBZ100 |

149/100

|

Φ650*450

|

11/15

|

26±1

|

41±2

|

15/18.5

|

2800

|

22.0

|

| JBZ200 |

287/200

|

Φ750*650

|

18.5/22

|

26±1

|

41±2

|

22/30

|

2650

|

21.8

|

| JBZ350 |

470/350

|

Φ900*740

|

30

|

25±1

|

41±2

|

37

|

2100

|

22.0

|

| JBZ650 |

840/650

|

Φ1100*885

|

45

|

25±1

|

36±2

|

55

|

1650

|

21.9

|

| JBL650 |

840/650

|

Φ1100*885

|

45

|

25±1

|

36±2

|

55

|

1650

|

21.9

|

| JBL800 |

1390/800

|

Φ1300*1050

|

75

|

23±1

|

36±2

|

75

|

1400

|

22.0

|

|

JBL1200

|

2030/1200

|

Φ1500*1150

|

9 0

|

21±1

|

33±2

|

90

|

1400

|

22.0

|

| JBL1500 |

2380/1500

|

Φ1500*1350

|

110/132

|

21±1

|

33±2

|

110/132

|

1350

|

22.6

|

*Note: The contents in this document are for information purposes only, and the actual product parameters depend on the specific design scheme.

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply