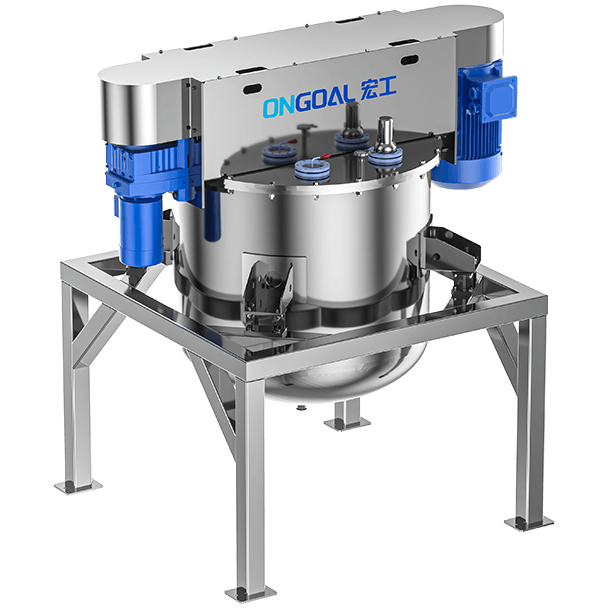

Product Features

Product Video

Video Introduction

Product Introduction

Scrapped structure with self-adaptive function and spoiler role, under the action of material resistance, always maintain the wall action, to reduce

01

Patented design of convex top for discharge valve to ensure discharge more thorough.

02

Standard three-blade paddle adopted in double-stage dispersion, high-speed dispersion and depolymerization performance maintained; special design to reduce the material spalsh when discharging.

03

The paddle adopts the patented design of open hinge with three points of contact, practical and hygienic, meets food-grade sanitation standards.

04

It adopts bi-directional sealing system that is better suited for vacuum degassing and air bubble removal for solid-liquid phase dispersion and mixing.

05

Product Specifications

High Gravity Material Dispense Mixer

Note: The materials used shall not produce chemical reaction during mixing, resulting in precipitation, gas and sharp temperature rise. The contents in this document are for information purposes only, and the actual product parameters depend on the specific design scheme

For expert turnkey solutions, email inquiry@ongoaltech.com, call +86 18820300825, or leave a message for a prompt reply