In a "long-haul journey," how can we ensure speed while reducing "fuel consumption"? ONGOAL TECH proposes the concept of a "Production Management Cockpit," empowering the energy-saving and emission-reduction in the manufacturing of lithium battery materials through digital intelligence.

As the world pursues green energy and sustainable development, the carbon reduction in new energy industry is booming. However, paradoxically, the production of lithium battery materials is a high energy consumer.

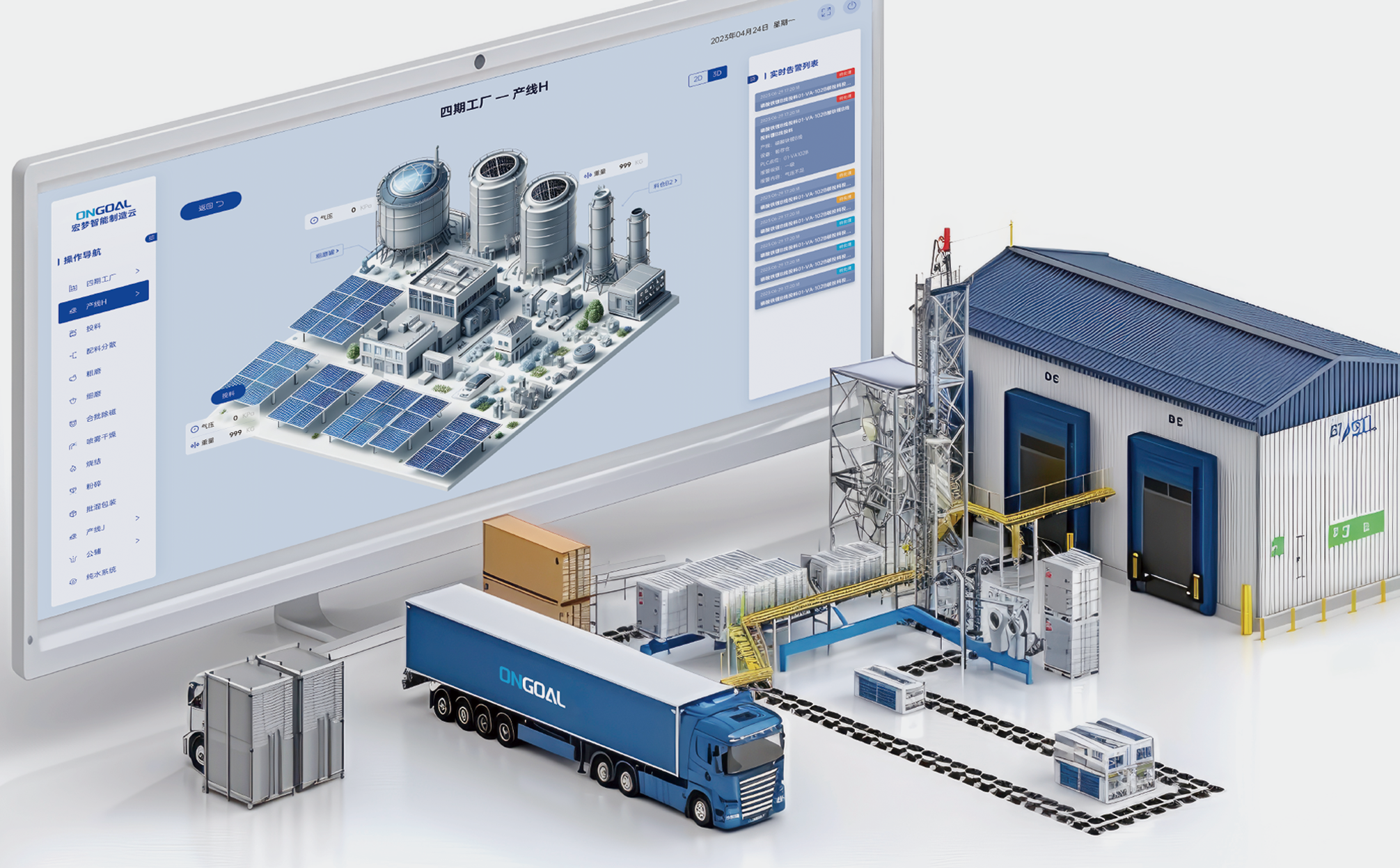

When high-energy manufacturing meets the emerging wave of digitalization, ONGOAL TECH uses the Hongmeng Intelligent Manufacturing Cloud Platform to strictly monitor energy consumption indicators in many key areas, providing decision support for the implementation of energy saving and consumption reduction.

Navigation Map: Comprehensive Energy Monitoring

How important is it to grasp the data required for production? Just as efficient navigation is inseparable from accurate map data collection, with the increasing maturity of digital transformation, data has become the fifth factor of productivity, unleashing tremendous potential.

The most important prerequisite for energy saving is having analyzable energy consumption data. ONGOAL TECH fully taps into the power of data, managing the consumption of water, electricity, gas, and other energy sources in an informationized and visual manner, forming a unified energy monitoring platform. In this "Production Management Cockpit," we achieve comprehensive monitoring, analysis, and assessment of the company's energy status, providing decision support for production, operational management, and energy optimization.

Unleashing Production Potential: Increased Capacity ↑, Decreased Energy Consumption ↓

The Hongmeng Intelligent Manufacturing Cloud Platform takes data as the entry point and quality as the core, effectively assisting lithium battery companies in realizing production process control and optimizing the use of production resources.

l Statistical analysis of production line, equipment, and product energy consumption, forming a unified energy monitoring platform.

l Automatic matching of production line output, calculating energy consumption data for different categories of output on each production line.

l Adjusting the production and processing time of different equipment according to peak and valley electricity usage.

l Real-time monitoring of the company's electricity quality to avoid fault risks.

l Through digital intelligence, we can greatly unleash production potential, achieve automatic control of equipment, improve equipment utilization, reasonably adjust the use of resources, greatly increase capacity, and reduce electricity consumption caused by equipment idling, rework, and abnormal conditions.

In addition to energy management, the Hongmeng Intelligent Manufacturing Cloud Platform can also provide the factory with more functions such as production scheduling, production execution, equipment management, and quality management.

With energy-saving and efficient professional equipment and processes, ONGOAL TECH helps lithium battery material customers strengthen carbon management, achieve an overall improvement in production and operational management, and social value, and move towards a green and sustainable future together.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information