From March 17-20, 2025, the 42nd International Battery Seminar & Exhibit concluded successfully at the Loews Royal Pacific Resort in Orlando, Florida. The event gathered numerous North American industry experts and corporate representatives to discuss the latest industry trends.

Amos, ONGOAL TECH's Overseas Key Account Director, delivered an insightful presentation on the company's latest advancements in battery manufacturing technology and key strategies for overseas operations, providing valuable insights for expanding global partnerships.

In his presentation titled "Practices Towards Higher Efficiency & Cost-Effectiveness in Battery Manufacturing," Amos analyzed seven key industrial trends in battery production:

● Scaling Up Equipment & Capacity: Larger equipment enhances production efficiency to meet the growing demand for batteries.

● Automation for Workforce Reduction: Automated systems minimize labor costs and human errors, streamlining the production process.

● Process Simplification: Optimized workflows reduce complexity, driving cost savings and efficiency improvements.

● Standardization: Unified processes and components ensure consistency and compatibility across production lines.

● Smart Manufacturing: Advanced technologies like AI and IoT enable intelligent monitoring and control, boosting productivity.

● Energy-Efficient Production: Implementing energy-saving measures reduces power consumption, lowering operational costs and environmental impact.

● Digitalization: Digital tools facilitate data-driven decision-making, predictive maintenance, and overall process optimization.

With extensive industry experience and a deep understanding of process innovation, ONGOAL TECH actively addresses the challenges and requirements of dry electrode preparation equipment. The dry process, which eliminates solvents, demands higher uniformity and consistency in subsequent procedures, requiring high-performance fibrillation mixing equipment.

Leveraging extensive experience and process research, ONGOAL TECH proactively addresses the industry's requirements and challenges in dry electrode preparation equipment. The solvent-free nature of dry processes necessitates higher standards of uniformity and consistency in subsequent procedures, requiring high-performance fibrillation mixing equipment. ONGOAL TECH's high-speed Integrated Homogenizing Mixer, specifically designed for dry electrode production, features ultra-high-speed cutting and shearing technology. With customizable agitator blades and dispersing discs, it meets various powder fibrillation needs, offering excellent adaptability and efficiency.

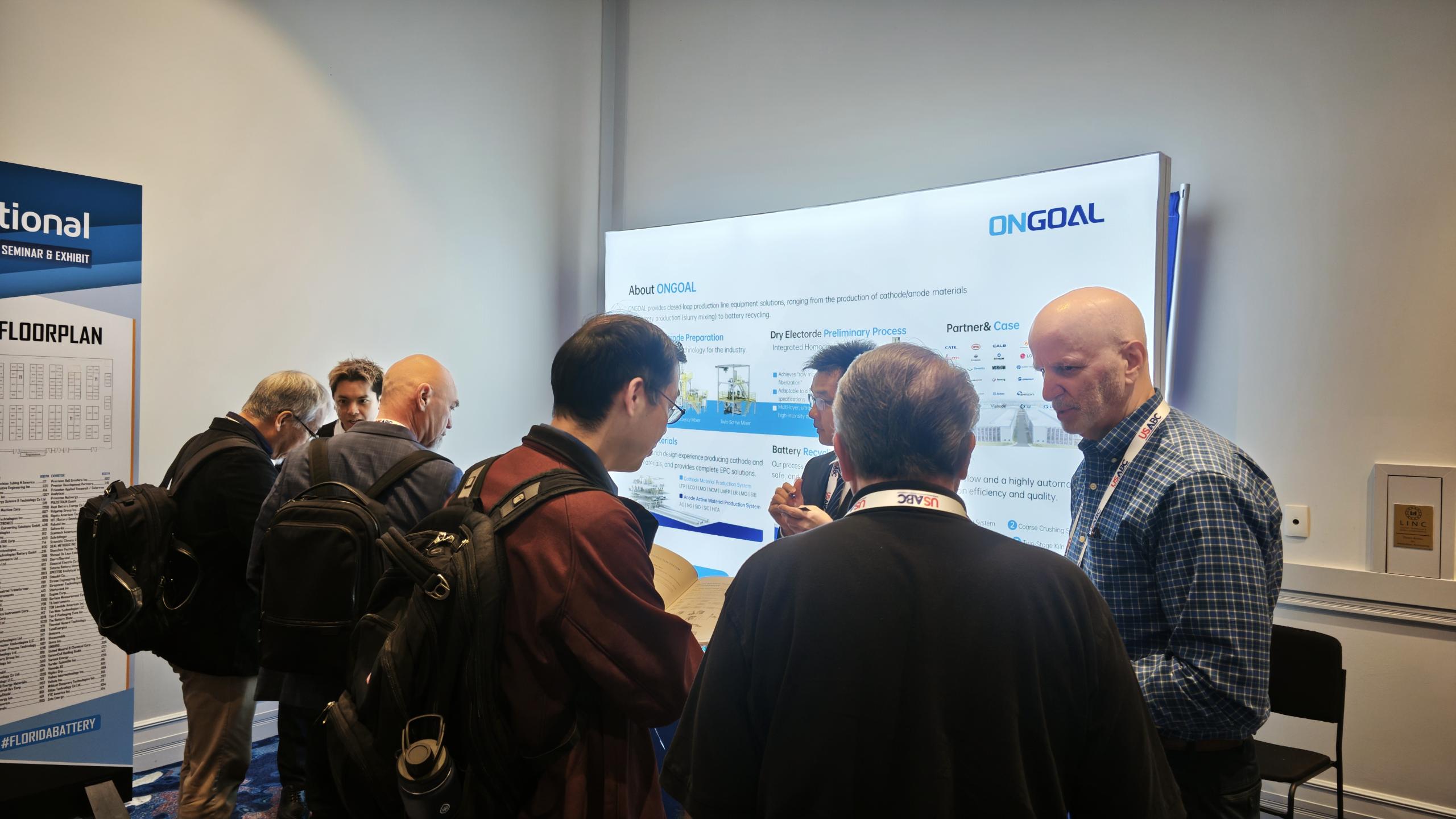

Amidst the rapid global expansion of the battery materials industry, Chinese enterprises' internationalization strategies are gaining increased attention. At the summit, ONGOAL TECH showcased its cathode/anode material production equipment and wet/dry electrode manufacturing technologies, drawing significant interest. Through interactive demonstrations and in-depth discussions, industry peers further recognized ONGOAL TECH’s technological expertise and forward-thinking market vision, reaffirming its status as a reliable global partner in battery manufacturing.

-

For expert turnkey solutions,

Email inquiry@ongoaltech.com

or contact us at +86 18820300825.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information