2022 Compounding Intelligent Manufacturing Conference(CIM) was held in Suzhou from 14 to 16 September. More than 700 industry professionals and experts from compounding modification, masterbatch, auxiliary and degradation modification industry attended the event, and ONGOAL TECH was invited to exhibit with its one-stop solution for plastic dosing system.

The Chinese government promises to peak carbon dioxide emissions by 2030 and strives to achieve carbon neutralization by 2060. With the pressure on environment protection and manufacturing costs, how to intensify the intelligent feeding of raw materials, boost the accuracy of material mixing, optimize the production environment and reduce management costs has become a pressing issue for plastic manufacturers. In this regard, ONGOAL TECH has accurately grasped the end-use demand and launched a one-stop solution for plastic dosing system, which has been well applied in many plastic enterprises such as Homelink, Silver, CGN Juner, Shiny, MINTH GROUP, DEBAO and SUCAIDA.

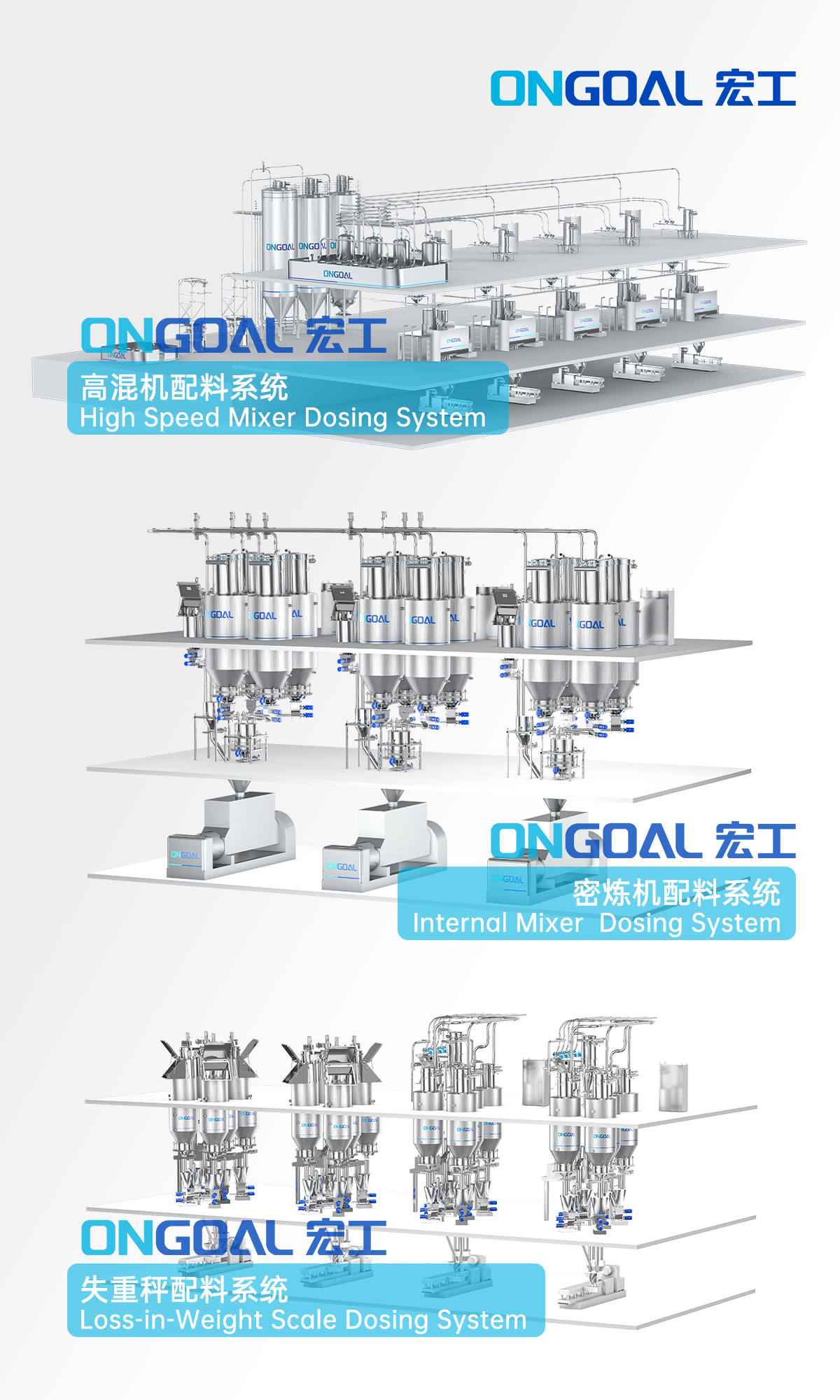

Sun Bowie, the key account director of ONGOAL TECH rubber and plastic business, said that the company has been deeply involved in the material handling field for more than 10 years and has hundreds of project data over the years, forming a standardized process based on different core equipment for rubber and plastic production such as high speed mixers, loss-in-weight scales and internal mixers, and then customizing the design according to the specific needs of customers to practically solve the problems.

Whether it is modified plastics, color concentrates, biodegradable plastics or wire and cable materials, all plastic manufacturers are currently in urgent need of solutions for the labor intensity of operators, dust and noise in the workshop and the consistency of quality of the products. Based on this, Sun Bowie believes, "Our future development is definitely in the direction of digital and intelligent."

To accelerate the achievement of this goal, ONGOAL TECH invests a lot of research and development funds and efforts every year, including equipment, system process, system software, solutions and many other levels.

For example, in order to solve the problem of dust that cannot be eliminated during the feeding process, ONGOAL TECH has developed its own automatic small bag unpacking machine, which solves the problem of difficulty in automatic bag unpacking of powder and the need for manual assistance, the powder packed in small bags can be automatically unpacking, which has outstanding advantages in improving the unpacking efficiency and reducing the feeding dust.

In addition to providing hardware equipment and services, ONGOAL TECH has also developed its own one-stop solution for intelligent manufacturing industrial internet, integrating industrial CNC equipment, PLC control systems, data monitoring systems, production management systems and the customer's own business management system, providing customers with an open, platform-based and intelligent production experience and helping them to achieve efficiency and high-quality.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information