Recently, Sun Bowie, Head of Rubber and Plastic Business Unit of ONGOAL TECH, was interviewed by CIM and gave in-depth answers on the topics of "Development and Opportunities of ONGOAL in Rubber and Plastic Industry in the Era of Uncertainty" and "Intelligent Manufacturing". This article contains some excerpts for your discussion.

Q: What are the highlights of ONGOAL TECH in the field of rubber and plastic compounding? Can you introduce the main business and the competitive advantages of the main products?

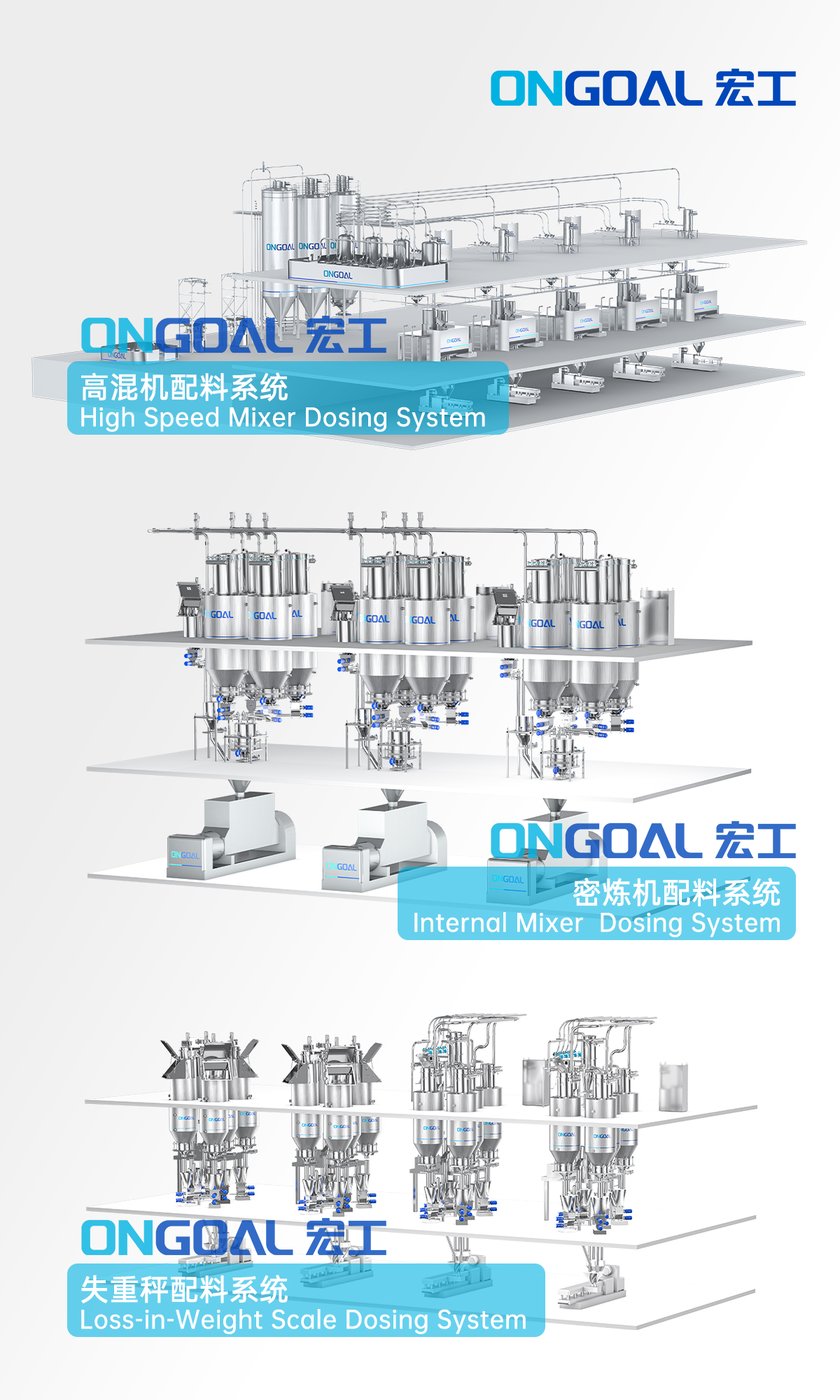

A: ONGOAL is positioned as a comprehensive service provider of material handling systems, providing customers with one-stop solutions for conveying and mixing systems in the field of rubber and plastic compounding. With the accumulation of technical strength and industry cases over the years, we have formed a standardised process based on different core equipment for rubber and plastic production such as high speed mixers, loss-in-weight scales and internal mixer, and then customised the design according to the specific needs of the customer to effectively solve the problems faced by the customer.

In terms of hardware, we provide customers with stable, reliable and high-precision system production lines to improve the consistency of product quality; in terms of software, we provide intelligent control systems that can integrate production control, monitoring and management systems through the construction of "intelligent manufacturing cloud" to achieve open, platform-based and intelligent integrated production of manufacturing operations.

Q: The industry has entered an era of uncertainty, and every company is looking for ways to withstand the uncertainty. Has ONGOAL been affected by the uncertainty?

A: Uncertainty contains the epidemic, the international situation, industrial upgrading and other factors. Rubber and plastic compounding is a traditional industry. We notice that international environment is always changing, and many customers' export business has been affected. The domestic situation is relatively stable, ONGOAL has not been affected too much. I think this is due to the technical accumulation and industry experience accumulated by ONGOAL over the years, and our continuous investment in technological innovation and research and development.

Q: Trending on intelligent manufacturing, especially in the event of CIM, can you tell us what kind of investment and achievements ONGOAL has made in intelligent manufacturing?

A: Intelligent manufacturing, in fact, is to reduce staffing, increase production efficiency and reduce management difficulties through production mode automation, digital transformation and other measures. Our future manufacturing industry will definitely develop in the direction of "unmanned, digital and intelligent", which coincides with ONGOAL mission of "making material handling simpler".

The R&D of intelligent manufacturing is also our direction of development. One is the development and innovation of equipment and process, and the other is the development and application of system software. In particular, our software development team has been working on the construction of "Intelligent Manufacturing Cloud", which has been applied in battery material industry and plastic industry.

Q: What is the effect of "intelligent manufacturing cloud" on rubber and plastic enterprises? Are there any successful cases or experiences that you can share with us?

A: ONGOAL "Intelligent Manufacturing Cloud" platform involves industrial CNC equipment, PLC control system, data monitoring system, production management system and the customer's own management system. Through the system integration and construction of "cloud technology", it can solve the problems of isolated information island, system silo and data collection which cannot guide production.

We say that intelligent manufacturing is a way to achieve greater value, not an end in itself. Whether they work or not depends on whether the enterprise has a strong need and determination to transform and upgrade. As a simple example, if a company adopts a system with functions such as real-time data collection, energy tracking and monitoring, and statistical analysis of production data, but these data are not fed back for improving and enhancing production efficiency, then this attempt is ineffective.

What ONGOAL doing is exactly extracting customers' demands, bringing them a more practical and visualized manufacturing system, improving their overall management of the factory and creating more value for them.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information