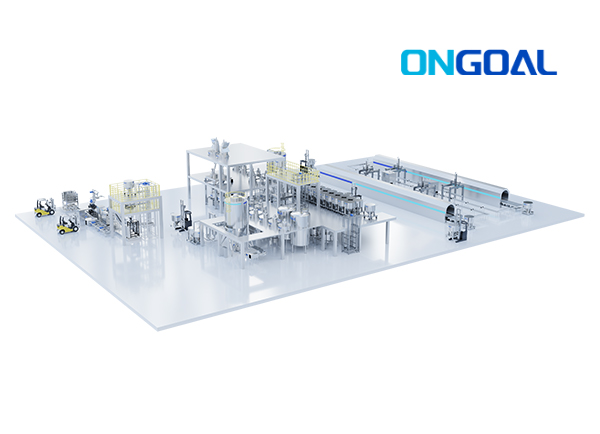

In the realm of ceramic powder and slurry production, efficiency, precision, and quality are non-negotiable factors. ONGOAL presents a cutting-edge solution that not only encompasses every aspect of the production process but also integrates advanced technologies to elevate manufacturing standards. From storage and feeding to packing, ONGOAL's comprehensive system ensures seamless operations while incorporating state-of-the-art features like AGV transport, enamel mixing, and efficient slurry defoaming. Let's explore how ONGOAL is revolutionizing ceramic production with its advanced features and unmatched capabilities.

Seamless Integration of Processes

At the heart of ONGOAL's solution lies a seamless integration of essential processes crucial for ceramic powder and slurry production. From storage and feeding to packing, every step is meticulously planned and executed to ensure maximum efficiency and precision. With features like automatic unpacking, precision batching, and efficient mixing, ONGOAL streamlines the production process, minimizing downtime and maximizing output.

Advanced Technologies for Enhanced Performance

What sets ONGOAL apart is its integration of advanced technologies designed to enhance performance and quality. With features like AGV transport, which ensures swift and efficient material handling, and enamel mixing, which guarantees uniformity in material composition, ONGOAL raises the bar for ceramic production standards. Additionally, technologies like spray granulation, microwave drying, and sintering further optimize the production process, ensuring superior quality and consistency in the final product.

Ensuring Quality and Safety

ONGOAL prioritizes quality and safety in every aspect of its system design. With features like toxic gas treatment (chlorine/hydrogen chloride), the system ensures a safe working environment by effectively neutralizing harmful gases emitted during the production process. Moreover, the system's ability to prevent the introduction of magnetic foreign objects and isolate materials from the external environment safeguards product integrity, minimizing the risk of contamination and ensuring consistent quality.

Efficiency and Reliability

Efficiency and reliability are at the core of ONGOAL's system design. With features like continuous and automated production, static conveying of spherical powders without easy breakage, and wear-resistant piping, ONGOAL guarantees uninterrupted operations and minimal downtime. Additionally, the system's efficient slurry defoaming capability ensures smooth and consistent processing, further enhancing productivity and quality.

In conclusion, ONGOAL's comprehensive solution for ceramic powder and slurry production sets a new standard in efficiency, precision, and quality. By seamlessly integrating essential processes and incorporating advanced technologies, ONGOAL revolutionizes ceramic production, offering unmatched performance, reliability, and safety. With features designed to ensure continuous and automated production, prevent contamination, and enhance material handling efficiency, ONGOAL empowers manufacturers to achieve superior results and maintain a competitive edge in today's dynamic market landscape.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information