In 2008, Chad Luo, actively exploring business opportunities in the thriving city of Dongguan, China, saw the pain points and bottlenecks in the powder processing industry's production efficiency and automation. Determined to "make a difference" for related industries, he founded ONGOAL TECH.

Since its inception, ONGOAL TECH has been committed to its mission of "making material handling simpler," providing businesses with material processing automation systems that are easy to invest in, install, operate, run, and maintain. This has propelled the development of material processing automation and achieved several milestone breakthroughs, helping global partners realize greater value.

Today, the rapid development of the new energy industry presents a clear opportunity, with the world's finest companies joining the race. To compete with these global powerhouses, we and our customers must jointly win the battle of innovation, cost, and green initiatives. Based on market demands for high safety, energy density, and cycling, the high-end capacity of the lithium battery industry remains in short supply. In response, the lithium battery industry is now focusing on cost reduction, efficiency improvement, and sustainable development.

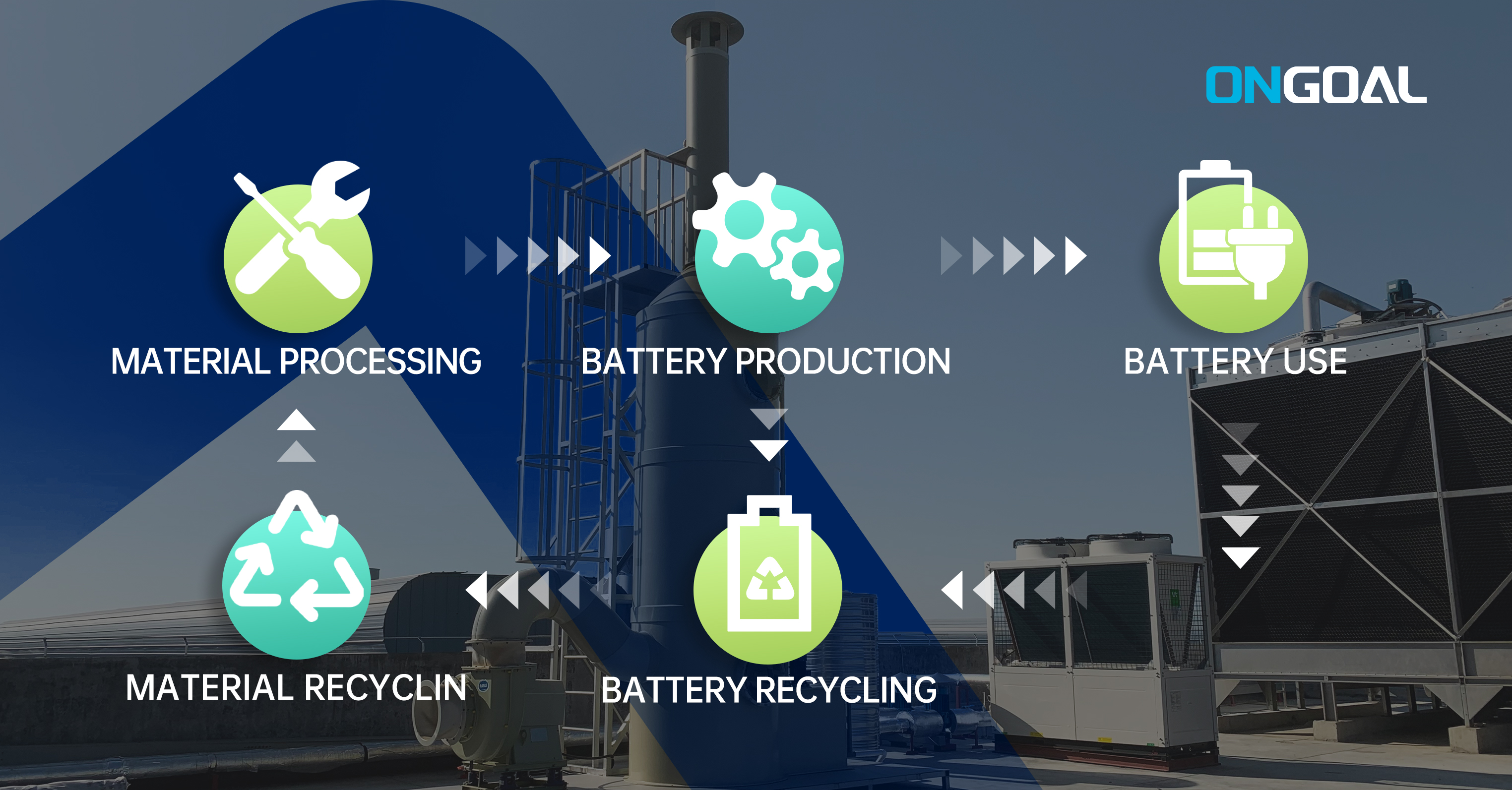

Below is ONGOAL TECH's battery lifecycle solution, covering the entire process from battery material manufacturing to battery recycling. Leveraging our in-depth understanding of battery production processes, we create efficient and intelligent production processes for customers, maximizing overall production efficiency.

01 Battery Materials: Innovative Processes

Battery material production is characterized by a single product, process manufacturing, large-scale production, and equipment-centric industry attributes. The production process involves various techniques such as mixing, coating, and sintering. Ensuring coordination and overall consistency between each process step has been a major challenge. Since its inception, ONGOAL TECH has positioned itself as a "comprehensive material processing service provider", offering integrated solutions for battery cathode and anode materials from process design and auxiliary engineering design to core equipment development and custom intelligent control systems.

ONGOAL TECH relies on its rich project experience in the field of lithium battery cathode and anode materials. Its integrated solutions are not limited to traditional battery materials such as lithium iron phosphate, ternary, and graphite. The company also actively explores emerging lithium battery material technologies and processes, such as lithium manganese iron phosphate, lithium-rich manganese acid lithium, sodium-ion, silicon-oxygen negative electrodes, silicon-carbon negative electrodes, and hard carbon negative electrodes, to meet the industry's continuously optimized formulation iteration requirements.

By combining an understanding of battery production and upstream and downstream processes, suitable process solutions and equipment can be selected according to the actual production needs of users. For example, addressing issues such as transportation blockages, insufficient capacity, and excessive energy consumption in the material production process, ONGOAL TECH has solved industry pain points by selecting appropriate parameters and equipment through years of research and experimental summary of battery material characteristics.

02 Battery Slurry Mixing: Efficient Smart Manufacturing

The battery slurry production process directly affects the performance, cost, and quality of battery products, making it a crucial part of the battery production process. ONGOAL TECH has accumulated deep insights into the slurry production process based on years of industry experience and continuously increased research and development investment in slurry production equipment. With the rapid development of new energy vehicles and renewable energy, battery technology is constantly innovating.

ONGOAL TECH established the Slurry Mixing Technologies Test Center in 2023, providing enterprises with material testing services for new formulas and technologies. Whether it's a dual planetary mixer, a new high efficient slurry production system, or a twin screw slurry production system, ONGOAL TECH has a variety of slurry equipment and technologies that can adapt to different materials and products, enabling the rapid and reliable production of various types of batteries. Our production line has a high degree of automation and intelligent management systems, ensuring maximized production efficiency and product quality stability.

With the transformation of power battery production processes and the iteration of material systems, future slurry processes such as low-solvent mixing and dry mixing will undergo comprehensive upgrades compared to traditional processes. While large-scale production of dry processes remains a challenge for the industry, ONGOAL is attempting to develop next-gen technologies such as twin-screw, super-mixing, and film-forming machines, adhering to forward-looking research and development to provide technical and equipment support for improving battery rate characteristics and cycle performance.

03 Battery Recycling: Completing the Loop

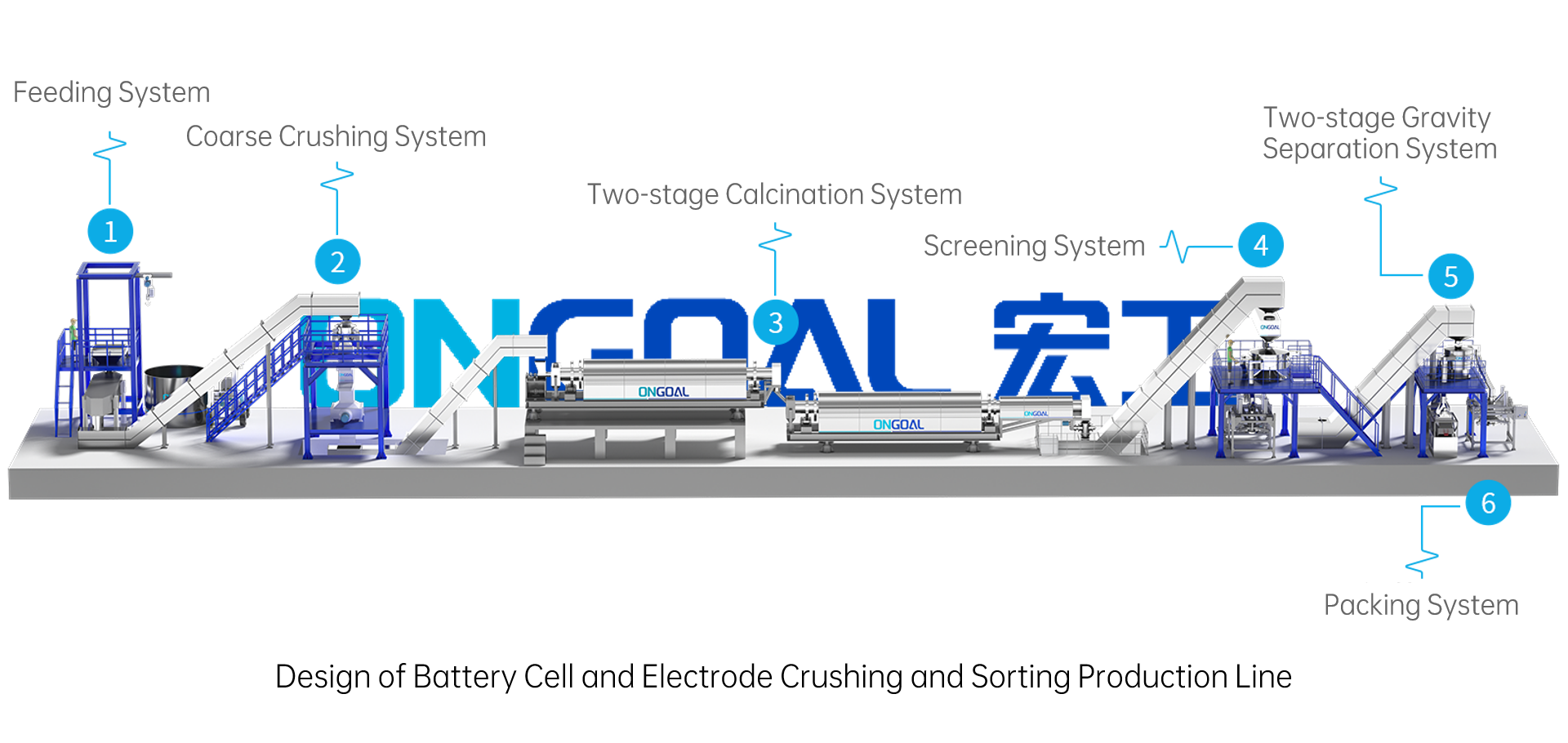

The recycling of waste batteries after hierarchical utilization contains immense economic and ecological value. With its expertise in professional knowledge and the deep utilization of equipment in the battery recycling industry, ONGOAL TECH can assist customers in developing or adjusting battery recycling processes with high flexibility and compatibility. The crushing and sorting of electrode pieces are key steps in the recycling of batteries. We adopt advanced crushing, decomposition, and refining processes for recycled electrode pieces, featuring a closed dust-free production process and highly automated safe and efficient design, ensuring excellent production efficiency and quality of products.

In our circular solution, the concepts of cost reduction, efficiency enhancement, scalability, and ecological closure are consistently applied. As a member of the battery industry chain, ONGOAL TECH continues to comprehensively and deeply deploy from cathode and anode materials to battery slurry and power battery recycling, empowering green, clean, and sustainable economic development.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information