Under the goal of carbon neutrality, the change of vehicle energy system are advancing rapidly, and the huge demand brings great opportunities and challenges to the upstream supply chain. ONGOAL TECH provides integrated solutions for the intelligent manufacturing of cathode and anode materials for battery industry chain enterprises, helping to push power batteries into the era of mass manufacturing.

On October 10-11, the 2022 GaoGong Lithium Materials Conference with the theme of "big demand expansion storm, big changes in the industry reshuffle" was held in Chengdu.

On October 11, Mr. Zhou Xianming, Sales Director of the Battery Materials business unit of ONGOAL TECH, delivered a speech on the theme of Lithium Material Production Line and Equipment with Mass Production Line and High Capacity.

In the context of the accelerated of global electric automobiles, power batteries are moving into the era of mass manufacturing, and it is expected that in the next two to three years, lithium-ion materials and lithium-ion equipment will be in a period of strong demand.

The lithium material production line will develop in the direction of "equipment massification, equipment automation, process simplification, production line standardization, manufacturing intelligence and management digitization", said Zhou Xianming, sales director of the battery material division of ONGOAL TECH, at the 2022 GaoGong Lithium Material Conference.

Equipment: Massification and Automation

On the way to equipment massification, ONGOAL TECH continues to research and develop core equipment, such as colter mixer, ribbon mixer, bulk bag packing machine, kettle dryer, etc. For example, the maximum volume of the ribbon mixer can reach 30m³, and the 6000L colter mixer has been applied in the battery industry.

The patented card slot technology is adopted for the ceramic lining of colter mix to solve the problem that the ceramic chips are easy to fall off in the production process. Ceramic and tungsten carbide coating adopt high-temperature ion spraying technology for more detailed protection against magnetic foreign bodies for battery industry requirement. The maximum specification can reach 4800L or even 6000L. The mixed batch quantity is large and the consistency of the mixture is good, which is more consistent with the trend of large-scale equipment in the industry.

Ribbon mixer adopts symmetrical intermittent spiral belt design, with good spiral shaft drive, excellent structure and high efficiency. It is up to 30m³with large batch quantity and short mixing time, competent in Anode/Cathode material batch mixing.

Process: Simplification and Standardization

The mass manufacturing of power batteries poses an extremely high challenge to the ability of lithium-ion equipment and key processes to be replicated and mass-produced in volume. Therefore, by standardizing and controlling the process flow, plant design, single equipment and electrical control, a large amount of repetitive design can be saved and the entire cycle time can be reduced for the customer.

Systems: Intelligence and Digitization

Facing the large-scale manufacturing in the TWh era, intelligent manufacturing is also an important launching point.

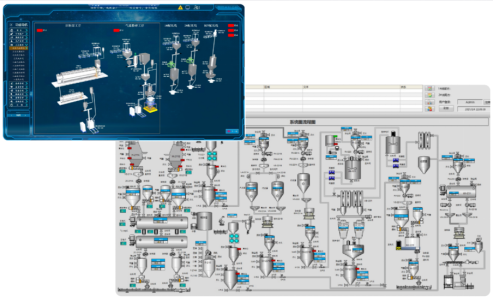

The software development team of ONGOAL relies on its deep understanding of battery industry chain manufacturing and independent R&D capabilities to provide integrated solutions for the intelligent manufacturing of cathode and anode materials for battery industry chain enterprises.

It covers the construction of infrastructure, data collection system, manufacturing execution system, energy management system and other segments, and with the deployment of data visualization such as electronic signage and mobile applications to enhance the customer's comprehensive factory management.

In addition, ONGOAL TECH is also actively exploring new lithium materials technology processes such as lithium manganese iron phosphate, lithium-rich lithium manganate, nano-ion, silicon oxygen anode, silicon carbon anode, hard carbon anode and other emerging lithium materials to meet the requirements of customers for mass manufacturing of power batteries in the TWh era.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information