High cost and non-environmental paper-plastic composite bags?

Low efficiency and unstable open-mouth packaging machines?

>>>

Shift from high cost, low efficiency to low cost, high efficiency with ONGOAL TECH's FFS Packing Machine. See how it effortlessly facilitates production transformation!

This intelligent packaging system automates all processes—film roll cutting, bottom sealing, bag forming, bag feeding, material filling, sealing, and conveying—in one high-speed operation. Its user-friendly interface makes it easy for operators to manage and maintain the machine. One person can supervise multiple machines, significantly boosting packaging efficiency and greatly reducing production costs.

The system supports multi-level user access and fault diagnosis, minimizing manual intervention while improving operational stability and efficiency.

Lower Cost Advantage

Compared to traditional open-mouth bagging, ONGOAL FFS packing offers higher sealing strength, faster efficiency, attractive packaging, and lower material costs.

Beyond operations, packaging material costs are also optimized. FFS film rolls cost about 1.5 yuan per bag, saving nearly 1 yuan per bag compared to paper-plastic composite bags. With an annual packaging volume of millions of bags, companies can save millions in packaging material costs, significantly reducing operational expenses.

Powder Adaptability

The FFS packaging system integrates FBS technology, combining FFS automatic bag forming with fully automatic bottom-up filling to minimize dust during powder packaging.

Additionally, features like micro-porous degassing, bag mouth cleaning, nano-rod air extraction, and exhaust venting can be flexibly combined to efficiently handle various special powder packaging requirements.

From Equipment to Complete Line

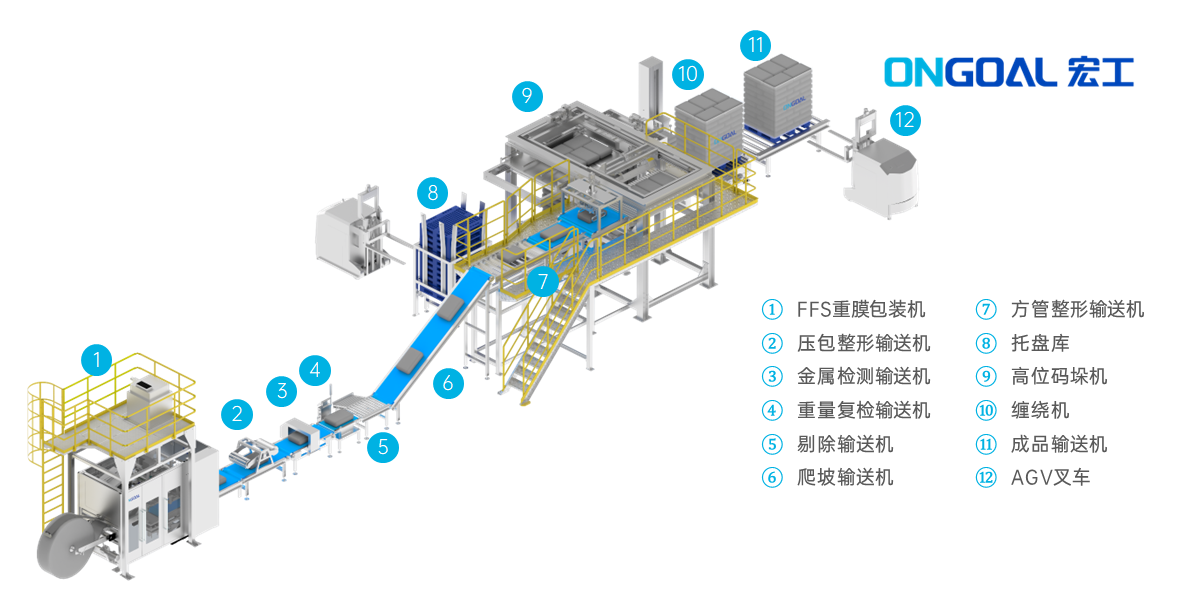

Beyond the core machine, ONGOAL TECH offers comprehensive one-stop packaging solutions, including shaping conveyors, metal detection, check weighing, rejection, robotic/high-level palletizing, stretch wrapping/sleeve wrapping, and AGV forklift transport.

The integrated packaging and palletizing logistics system enables a full digital upgrade from individual machine management to system-wide control, providing enterprises with a high-efficiency, simple, and intelligent production experience.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information