In the field of material handling, long-standing issues such as low automation levels in feeding processes, dust pollution, and unstable production capacity have been difficult to overcome.

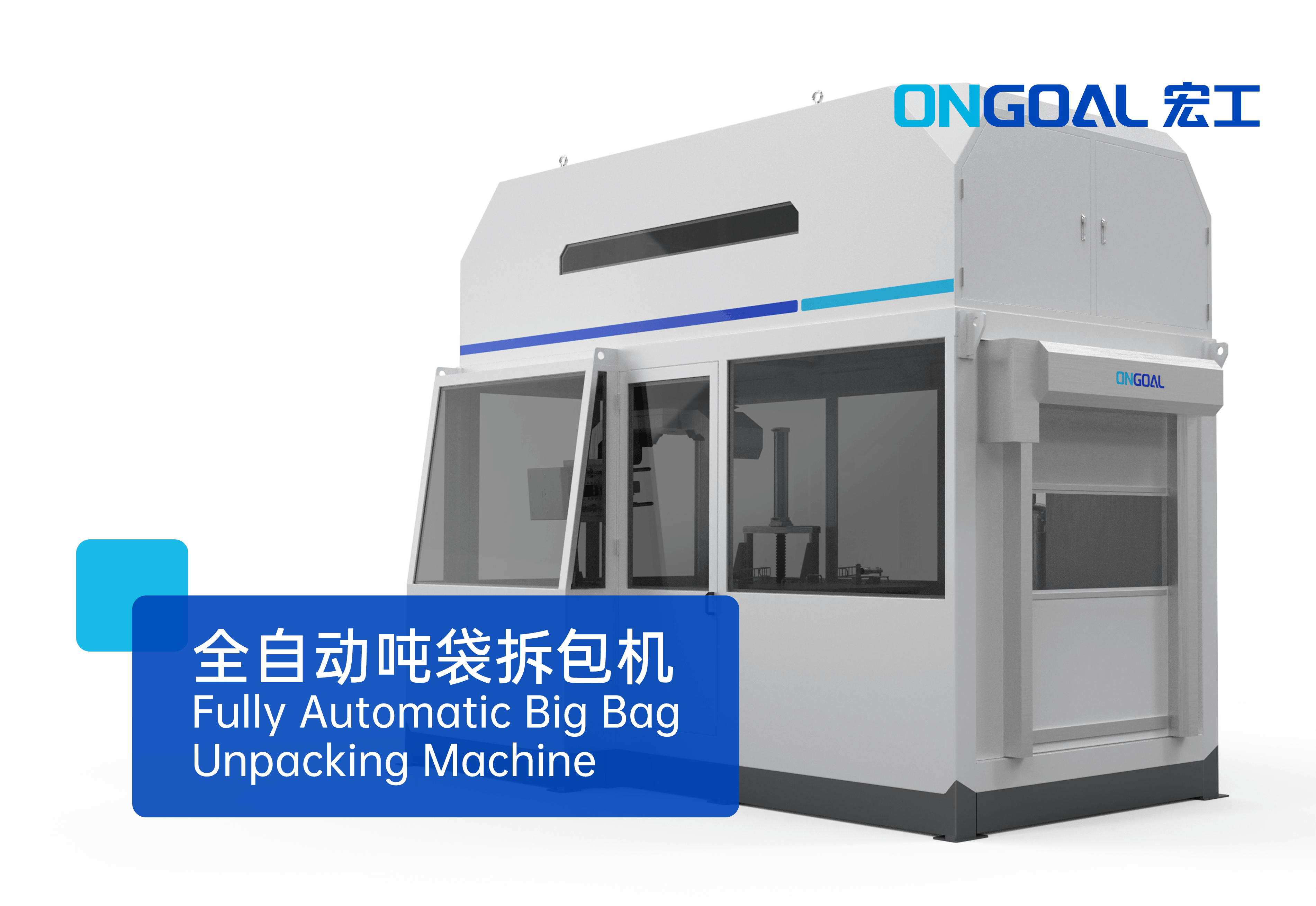

Recognizing market demand, ONGOAL TECH has launched a range of automated feeding equipment, including the fully automatic big bag unpacking machine, filling industry gaps and solving customer pain points through technological innovation, aiding companies in their transformation and upgrading.

Strong Demand for "Machine Substitution" in the Feeding Process

In various industries, traditional feeding methods often rely on manual unpacking or cutting bags open for direct feeding. This not only results in high labor intensity for workers but also leads to issues like dust pollution and environmental contamination, which are hard to control. Numerous cases of pneumoconiosis are alarming.

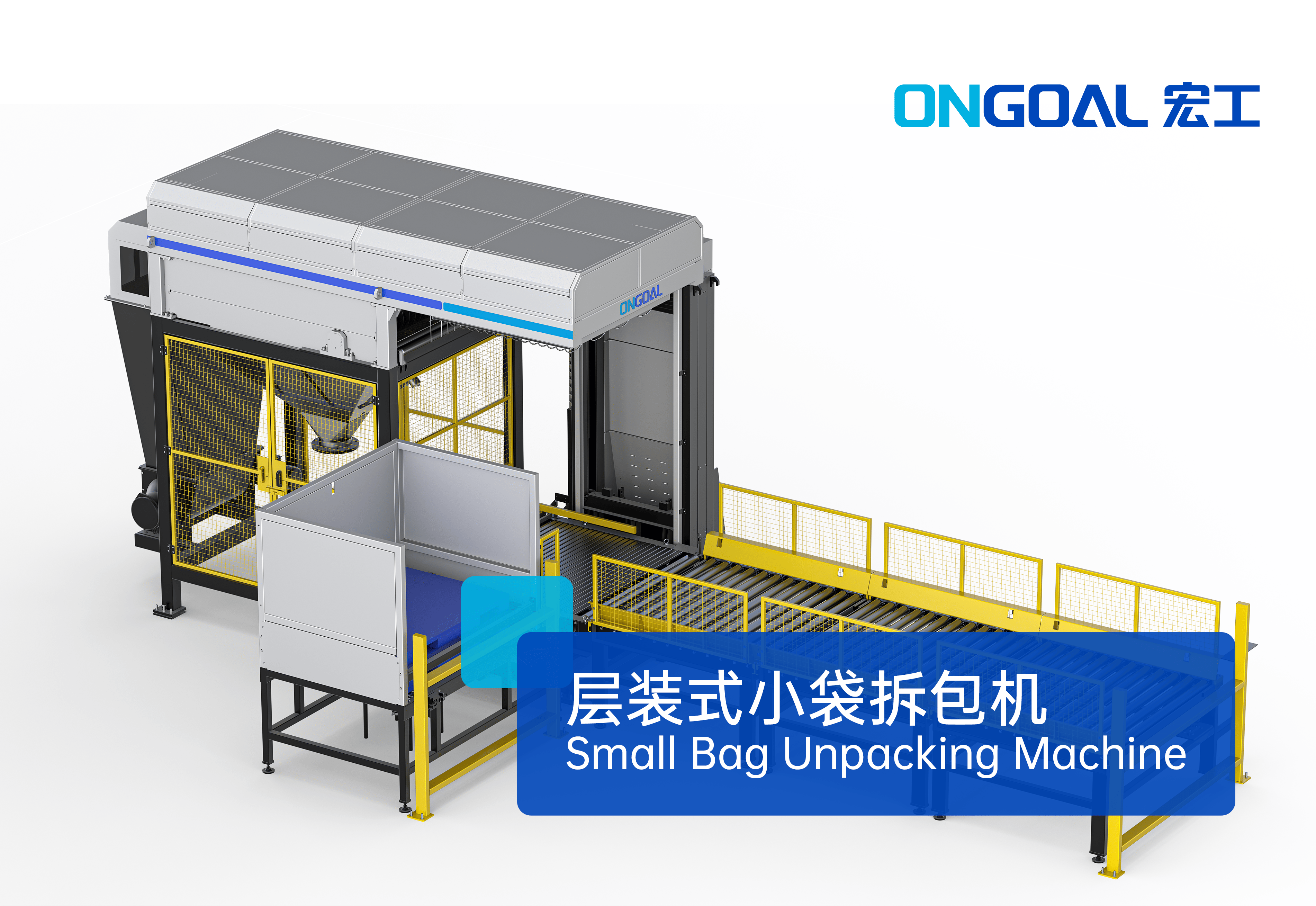

With the rise of large-scale production, ONGOAL TECH has focused on innovations in material handling technology, offering a range of unpacking and feeding equipment and technologies, including big bag unpacking stations, small bag unpacking stations, bulk truck feeding systems, and container feeding systems, providing the industry with a clean and dust-free production environment.

However, existing unpacking and feeding equipment still cannot fully address the high reliance on manual labor. In the current complex and ever-changing international landscape, market uncertainties have amplified the demand for "machine substitution." Many manufacturing enterprises recognize that advancing production automation, digitalization, and intelligence is not only a necessary path to address labor shortages and improve production efficiency but also crucial for enhancing enterprise resilience and competitiveness.

Particularly in ONGOAL TECH’s key business sectors of battery materials and battery slurry, there is a growing demand for cost reduction, efficiency enhancement, and technology-driven solutions, setting higher standards for equipment manufacturers.

Against this backdrop, ONGOAL TECH has directly tackled issues in the battery material feeding process, such as low efficiency, low automation, poor working environment, and unstable production capacity.

This year, the company launched the fully automatic big bag unpacking machine, which offers advantages such as a 300% increase in feeding efficiency, ≤0.03% material residue rate, fully enclosed dust-free feeding, and a ≥99.99% bag grabbing success rate.

This innovation has successfully reduced the high manual involvement in the battery material feeding process, filling industry gaps and further empowering cost reduction and efficiency enhancement in lithium battery manufacturing. It has also significantly contributed to the industry’s goal of achieving "dark factories."

Product Extensions Based on Core Advantages

A deep analysis of ONGOAL’s development trajectory reveals that the expansion of its product line or technology development path is gradually derived from ONGOAL TECH's core strength in "material handling technology." For example, the company has achieved breakthrough results in areas such as feeding, weighing, mixing, drying, grinding, conveying, and packing, providing one-stop material handling solutions for the industry through proprietary software development.

Among these, automated feeding, as the foremost process in material handling, is naturally a key development area for ONGOAL. In addition to the aforementioned fully automatic big bag unpacking machine, the company has also introduced fully automatic clean small bag unpacking machines and small bag unpacking machine, fully covering the unpacking and feeding needs of various industries and packaging forms.

Today, the fully automatic big bag unpacking machine and fully automatic layered small bag unpacking machine, as typical examples of automated feeding equipment, have been applied in multiple smart factories, helping customers achieve efficient operation and clean production.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information