Amidst the rapid development of the global electrical vehicle market, the retirement wave of power batteries has quietly arrived. This trend has not only spurred the vigorous vitality of the power battery recycling industry but also made it a hot field that attracts global attention and competitive layout. Against this backdrop, ONGOAL Technology Co., Ltd. (hereinafter referred to as "ONGOAL") has introduced a solution for the pre-treatment section of battery recycling, driving the high-quality development of battery recycling and empowering a green, clean, and sustainable economy.

Figure: ONGOAL battery recycling pilot line

Challenges and Opportunities Coexist in Power Battery Recycling

Since 2010s, battery recycling industry has undergone tremendous changes, from initial rapid development to later unregulated growth, and now to standardized development, the industry has gradually matured. However, how to recycle in an environmentally friendly and efficient manner to ensure the healthy development of the industry remains a key issue to be resolved.

Retired batteries need to go through several processes such as screening, crushing, and smelting to extract valuable metals like nickel, cobalt, and manganese, but this process has high technical barriers, and improper processing can easily cause environmental pollution. In addition, the battery recycling industry is still in its infancy, the profit model is not yet mature, and the industry ecosystem needs further construction and improvement.

ONGOAL: Battery Recycling Solutions Attract Attention

In response to the current technical bottlenecks and market pain points in the field of battery recycling, ONGOAL has focused on the pre-treatment section of battery recycling, committed to promoting the green, clean, and sustainable development of the industry through technological innovation and equipment upgrades. It is reported that ONGOAL battery recycling solution covers various stages including battery pack/module disassembly, cell fine disassembly, and cell/foil crushing recycling, meeting customer needs comprehensively.

l Battery pack/module disassembly solution: Achieve flexible switching from semi-automatic to automatic, improve disassembly efficiency, reduce labor intensity, and ensure operation safety.

l Cell fine disassembly solution: Use automated cutting technology to improve disassembly accuracy, reduce impurity mixing, and enhance recycling quality.

l Cell/foil crushing and recycling solution: Optimize the crushing process to achieve efficient extraction of valuable metals while reducing environmental pollution.

Empowering a Green, Clean, and Sustainable Economy

It is understood that the informatization of waste battery recycling and reuse is a current focus of work. With the help of advanced information technology, traceability management of waste batteries, transparency of recycling processes, and intelligent data analysis can be achieved, improving recycling efficiency and management level, and providing strong support for industry development.

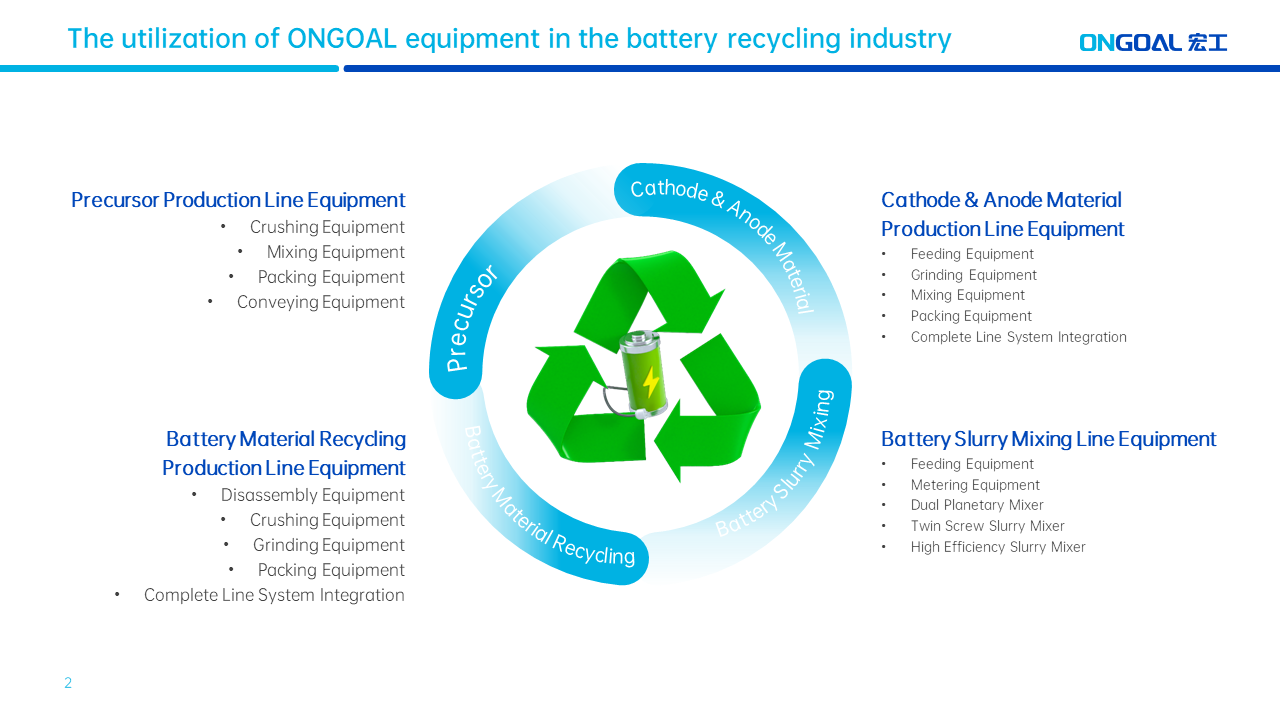

As an important part of the battery industry chain, ONGOAL continues to deepen its layout, forming a complete industrial chain closed loop from battery slurry, cathode and anode electrode materials to power battery recycling. ONGOAL introduces that the company has an independent software BU, focusing on the R&D of industrial automation software, capable of providing customers with information system integration services based on years of technical experience and a stable equipment supplier system, including MES and SCADA systems, to provide comprehensive enterprise operation and management capabilities, fully empowering the green and sustainable development of the battery recycling industry.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information