In powder coatings, intelligent unmanned factories are an essential direction for future transformation and upgrading. At ONGOAL TECH, we provide customers with intelligent bulk ingredient mixing system solutions, helping them achieve automated, specialized, and scale production.

Pain Points

- Frequent changes in product formulations

- Multiple and diverse material categories

- High maintenance requirements of the existing system, frequent automation issues

System Benefits

- Centralized management of raw materials

- More economical, environmentally friendly, and efficient operations

- Streamlined product formulation management for optimization

- Automatic identification and error prevention measures

- Seamless integration with existing systems to retain data and progress

This system consists of three stages: material storage, metering and batching, and dust collection. Through the production management system, the entire production process is automated and controlled, meeting the overall operational requirements of the system.

Centralized management of raw material storage

The incoming raw materials are securely connected to the system using fully sealed connections, preventing dust from spreading to the workshop. Centralized management of raw material storage is implemented to effectively reduce product waste and facilitate unified management.

This case involves a wide variety of materials, among which more than 15 types tend to adhere to the walls and form material hang-ups in the storage, while 20 types of materials are prone to arching and bridging during the discharge process.

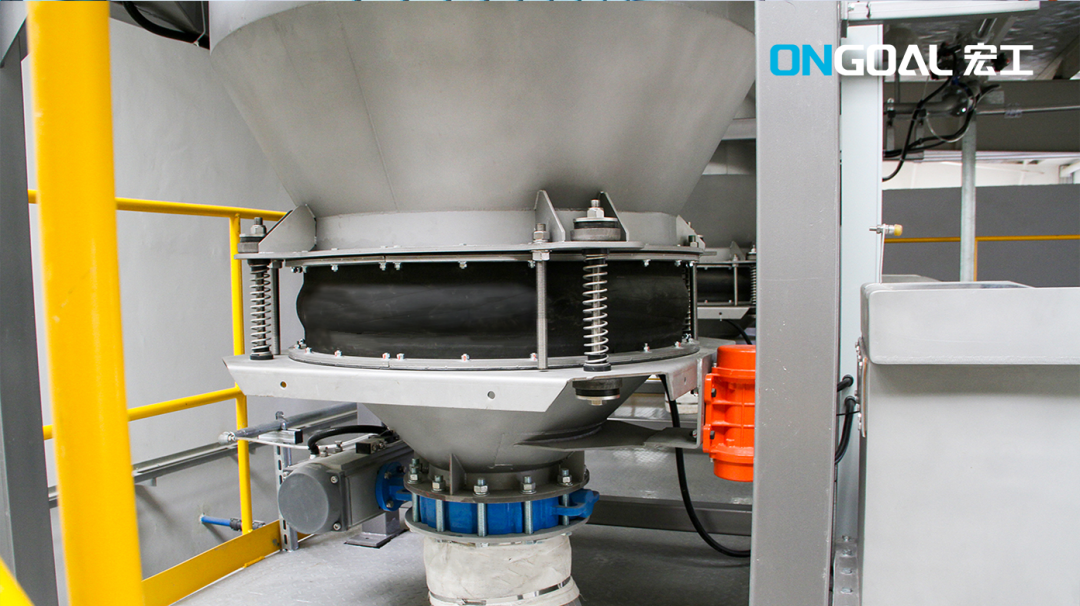

Based on the different characteristics of the materials, ONGOAL TECH has equipped the silos with various arch breaking devices. For materials with poor flowability, a vibrating hopper is used to prevent bridging and ensure smooth discharge of the materials.

Screw metering to prevent cross-contamination.

The materials are metered using a screw mechanism, and for materials with poor flowability, the screw configuration includes a stirring device. This helps prevent bridging of materials inside the screw and ensures uniform feeding of the screw.

Different materials are conveyed by separate screw metering systems, effectively avoiding cross-contamination.

In this project, the bulk materials are measured in a ratio of 6:1, while the auxiliary materials are measured in a ratio of 2:1. This not only ensures production efficiency but also significantly reduces the number of metering stations, resulting in cost savings.

Furthermore, all the ingredients are conveyed and metered through a closed pipeline system, with minimal manual intervention. This reduces the risk of color variations caused by manual weighing, ensuring product consistency and uniformity.

Automatic identification and error prevention in the batching process

The batching station utilizes a chain conveyor system, where the material barrels are automatically docked with the batching line according to the formula. RFID cards are set up to read and write information about the material barrels. When a barrel is moved to the batching station, the system reads the information from the barrel to determine if it should be used for batching at that station, providing automatic identification and error prevention.

All formulations in the workshop are managed through automation, with batching quantities, batching accuracy, and other parameters automatically recorded to generate reports. By accumulating data, further optimization of product formulations and varieties can be achieved.

Latest Information

Latest Information