Lithium battery cell slurry stirring is a mixing and dispersing process that affects the product quality by more than 30% in the entire production process of lithium-ion batteries, and is the most essential part of the whole production process.

70% of the cell quality is related to the quality of the electrode pole and 70% of the electrode pole quality is related to the quality of the slurry. Therefore, manufacturing slurry is equal to half of the manufacturing cells. Homogenization is the first and core task of cell manufacturing. In addition to the slurry mixing process, the cell process in the laboratory is usually more delicate than the commercial cell process. This also indicates that homogenization is also a difficult task in battery manufacturing.

The main purpose of lithium-ion battery dispersion is to homogenize the active material, electrical conductive agent, binder, etc. in the solvent in a certain mass ratio so that the electrode pole coating forms a stable particle size with a certain viscosity, and the lithium-ion battery process is intended to prepare for production.

The requirements for an ideally sized electrode are small, uniformly dispersed particles of active substance and no agglomeration. The particles of the conductive agent form a thin layer. They are dispersed into a conductive network that maximizes the attachment of the active substance particles to the collector (preferably fine particles) to ensure the high current density of the cell.

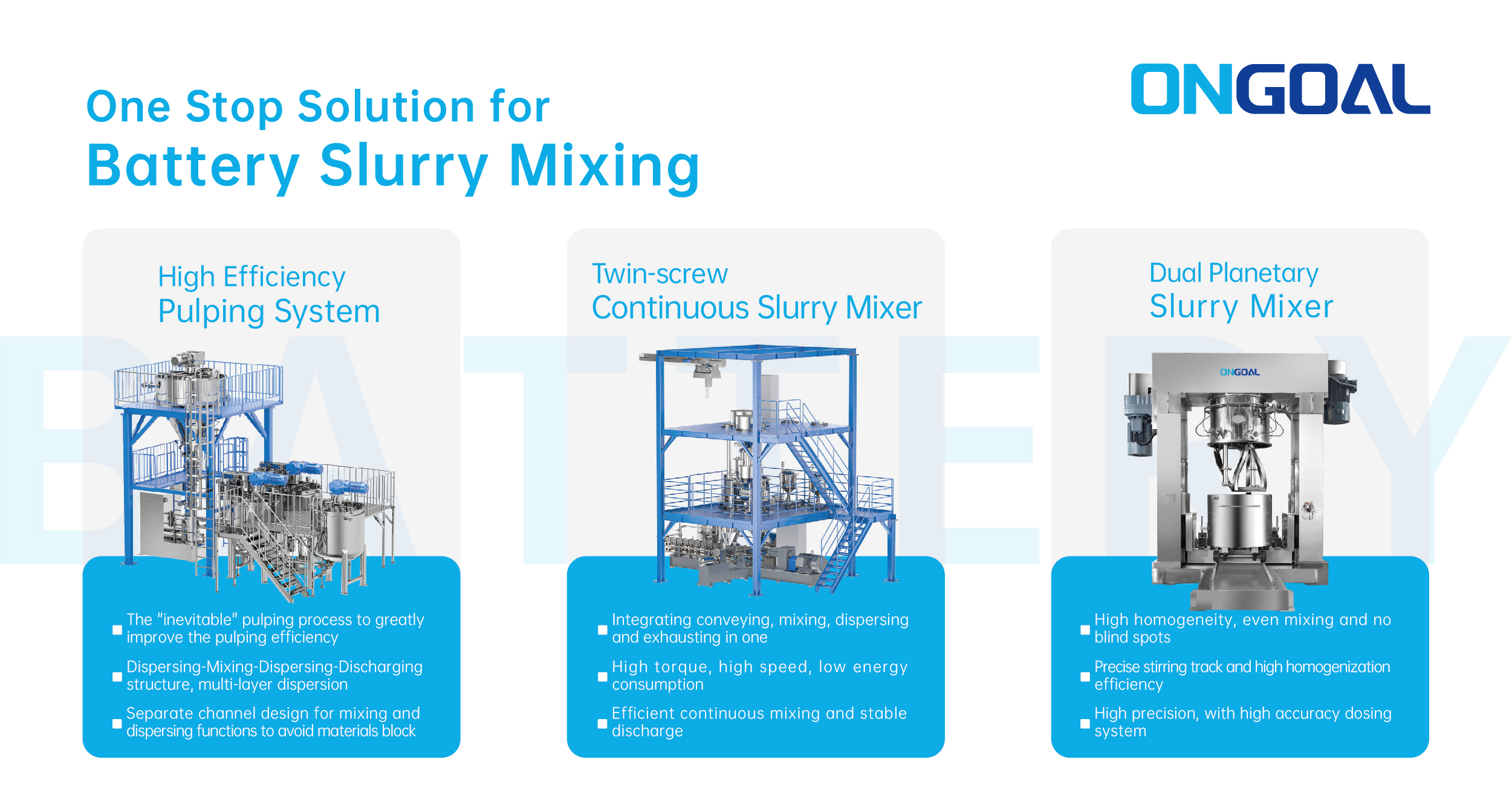

Based on the pain points in the industry, ONGOAL developed 3 kinds of the slurry mixing systems.

Used for mixing, homogenization, and dispersing of powder and liquid materials. The dispersing disc and stirring paddles realize revolution and rotation simultaneously. The frequency converter can adjust the speed. The special mixing method makes the materials strongly dispersed and pressed to ensure materials are fully dispersed and mixed.

NEW HIGH EFFICIENCY SLURRY MIXING SYSTEM

The new high efficiency slurry mixing system adopts the powder and liquid feeding at the same time, and the narrow and long path of the dispersion chamber makes sure all slurries pass through the effective dispersion zone.

The equipment adopts a modular twin-screw structure, integrating conveying, mixing, dispersing, and exhausting in one, which can realize continuous material processing and continuous discharging, and realize free collocation to meet the demand of different working conditions and lower cost and energy loss caused by a single function.

Upgrading from a PD mixer, ONGOAL become one of the few corps in the industry mastering three kinds of the slurry mixing process equipment at the same time. What’s more, it is a huge breakthrough in the industry that the slurry mixing system completes the entire batch mixing in just 1.5 hours with powder feeding, liquid feeding, and high efficiency slurry mixing. In the future, ONGOAL will continue to upgrade its technology to provide more advanced solutions for the battery industry.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information