The rapid development of the new energy vehicle industry has continued to exceed industry expectations. According to a recent research report by market institutions, global electric vehicle sales will exceed 20 million units by 2025. The estimated sales, which are much higher than the previously estimated 14 million units, are mainly due to the accelerated popularity of electric vehicles in the Chinese market. Electric vehicles are expected to account for nearly a quarter of all new vehicle sales worldwide by 2025.

Global power battery manufacturers are expanding production. According to public data, by 2025 CATL capacity planning about 670GWh, BYD planning more than 400GWh, EVE planning more than 300GWh, GOTION planning more than 300GWh, SVOLT planning up to 600GWh, CALB planning 500GWh; LG new energy planning up to 520GWh, Panasonic planning up to 160GWh, and SKI planning 200GWh.

The consensus of the industry is that in the next five years, the global power battery market will usher in a blooming period and rapidly enter the TWh era. It gives the equipment enterprises, with strong technical innovation ability and product strength, the opportunity to show their skills.

Homogenization is the first process of Li-ion battery cells production, and the quality of the slurry has a critical impact on the cells. Especially in the era of TWh for larger scale production, it is urgent for lithium battery manufacturers to choose efficient and stable slurry equipment with excellent performance.

ONGOAL TECH specializes in material handling automation and provides one-stop solutions for battery production, including storage, metering, conveying of raw materials (powder, slurry and solvent), homogenization, and slurry conveying, making fuel cars a history-while long overdue!

Entering lithium battery industry with material production lines and lithium battery slurry mixing in 2015, our systems, equipment and services have been widely used in new energy, chemical, plastics and other industries, and have been recognized by CATL, BYD and LyondellBasell etc.

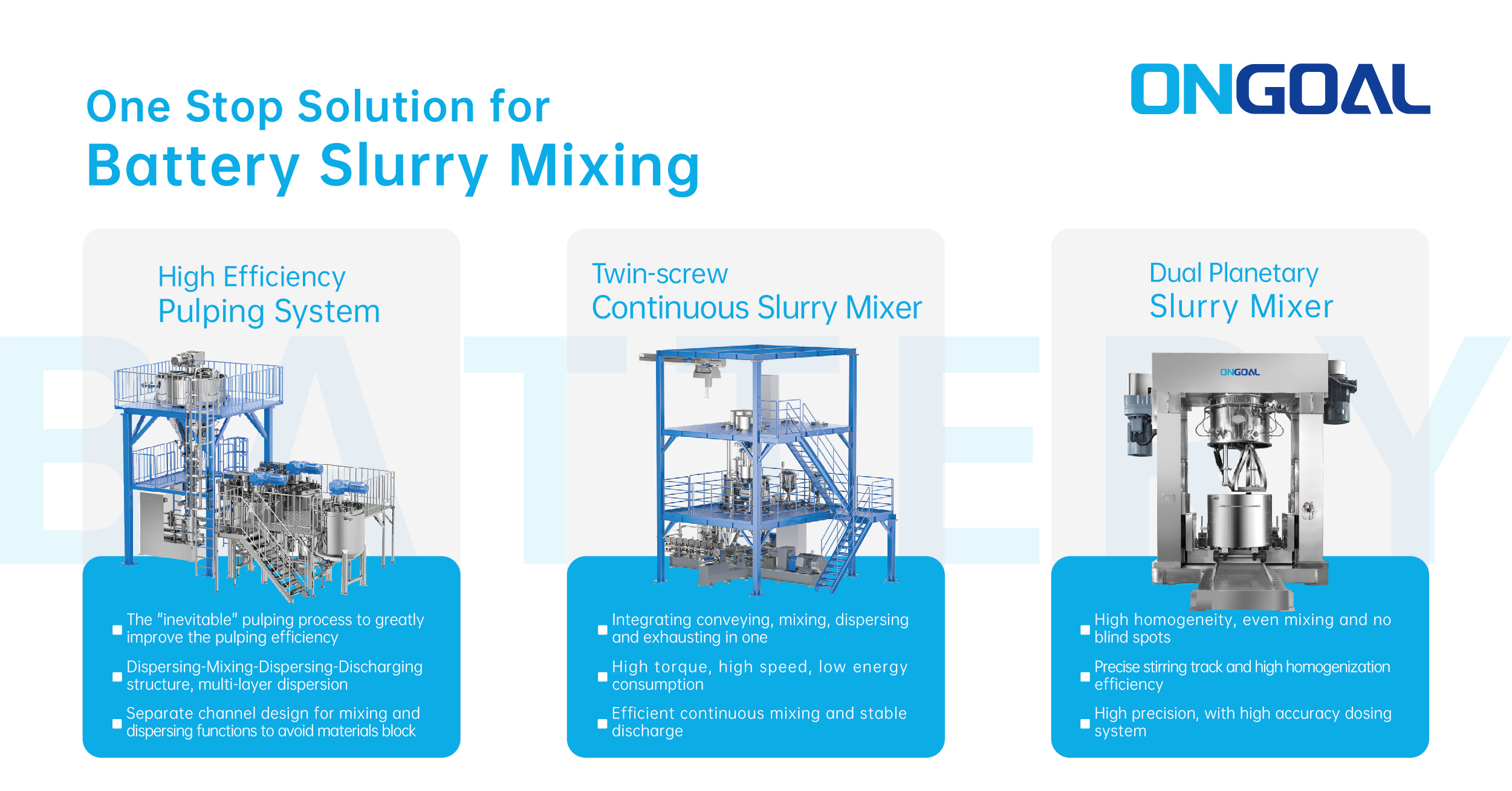

In the field of battery homogenization, there are 3 mainstream pulping processes: Dual Planetary Mixer, Twin-screw Continuous Slurry Mixer and High Efficiency Pulping System. ONGOAL TECH has continuously increased its R&D investment in the forward-looking research of pulping equipment, and is one of the few enterprises in the industry that master three kinds of process equipment at the same time.

ONGOAL owns complete scientific research, design, production, sales and software development service systems. We support customers with diversified automation solutions for material processing such as material storage, automatic feeding, pneumatic conveying, material metering and dosing, mixing, intelligent control, etc. ONGOAL's products and systems are widely used in new energy, fine chemicals, food and medicine, rubber, plastics and other industries. ONGOAL is your trustworthy material handling expert.

Get expert turnkey solutions!

Get expert turnkey solutions!

Latest Information

Latest Information